Industry News

How Does a Faulty EGR Pipe Affect My Car's Performance?

How Does a Faulty EGR Pipe Affect My Car's Performance?

It’s a scenario many drivers have experienced. You’re driving along, and suddenly, your trusted vehicle feels different. Maybe the check engine light flickers on, or you notice a rough idle when you’re stopped at a traffic light. Perhaps acceleration isn’t as responsive as it used to be. While these issues can stem from a variety of sources, one often-overlooked culprit could be a small but significant component: the Exhaust Gas Recirculation (EGR) pipe. This unassuming tube plays a critical role in your engine's health and efficiency, and when it fails, the effects can be both noticeable and problematic. This article will delve into the world of the EGR system, explain the specific function of the EGR pipe, detail the symptoms of a malfunction, and guide you through the process of understanding and resolving the issue.

Understanding the EGR System: A Simple Explanation

Before we focus on the pipe itself, it's helpful to understand the system it belongs to. The Exhaust Gas Recirculation (EGR) system is an essential part of a modern vehicle's engine management strategy. Its primary purpose is to reduce the formation of nitrogen oxides (NOx), which are harmful pollutants created during the high-temperature combustion process in your engine.

Think of your engine's combustion chamber as a very hot, high-pressure environment. When temperatures get excessively high, the nitrogen and oxygen in the intake air can combine to form NOx gases. The EGR system's job is to keep these combustion temperatures in check. It does this by diverting a small, controlled amount of exhaust gas—which is already inert and has a lower oxygen content—back into the engine's intake manifold to be mixed with the fresh air-fuel mixture.

This "recycled" exhaust gas doesn't burn. Instead, it absorbs heat and effectively reduces the peak temperature inside the combustion chamber. By lowering this temperature, the conditions that create NOx are significantly minimized. This process not only helps your vehicle meet emissions standards but can also prevent engine-damaging detonation or "knocking" under certain conditions.

The Key Players in the System

The EGR system is composed of a few key components that work together:

- EGR Valve: This is the brain of the operation. The valve, controlled by the engine's computer (ECU), opens and closes to regulate precisely how much exhaust gas is allowed to re-enter the intake manifold.

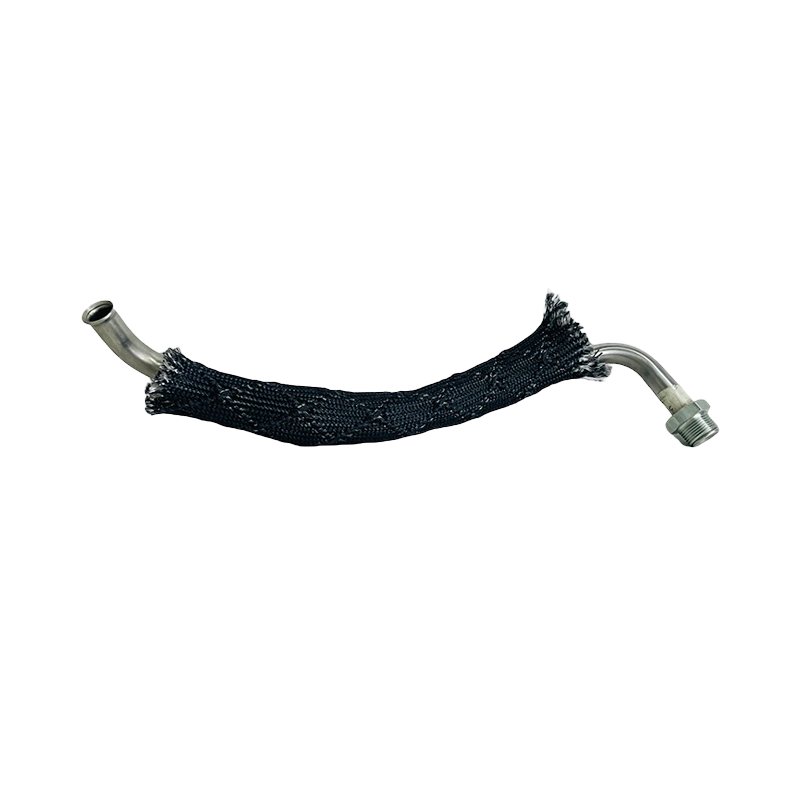

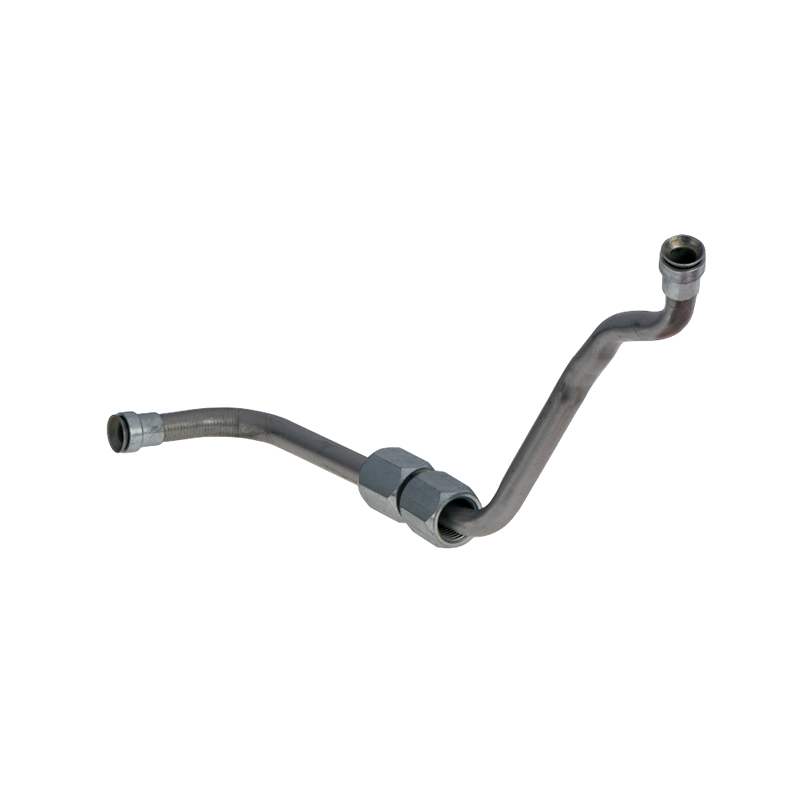

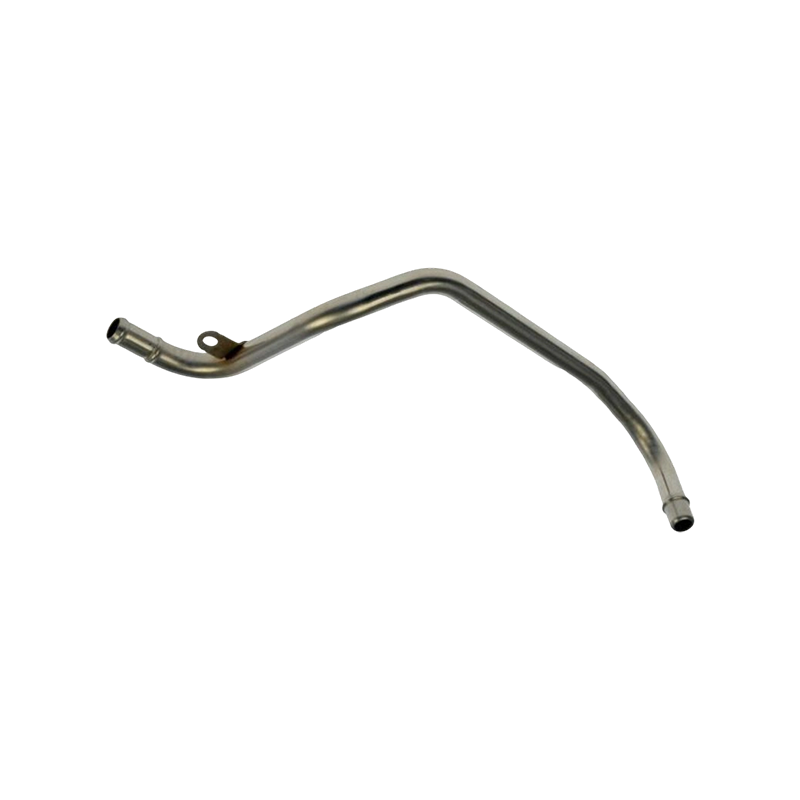

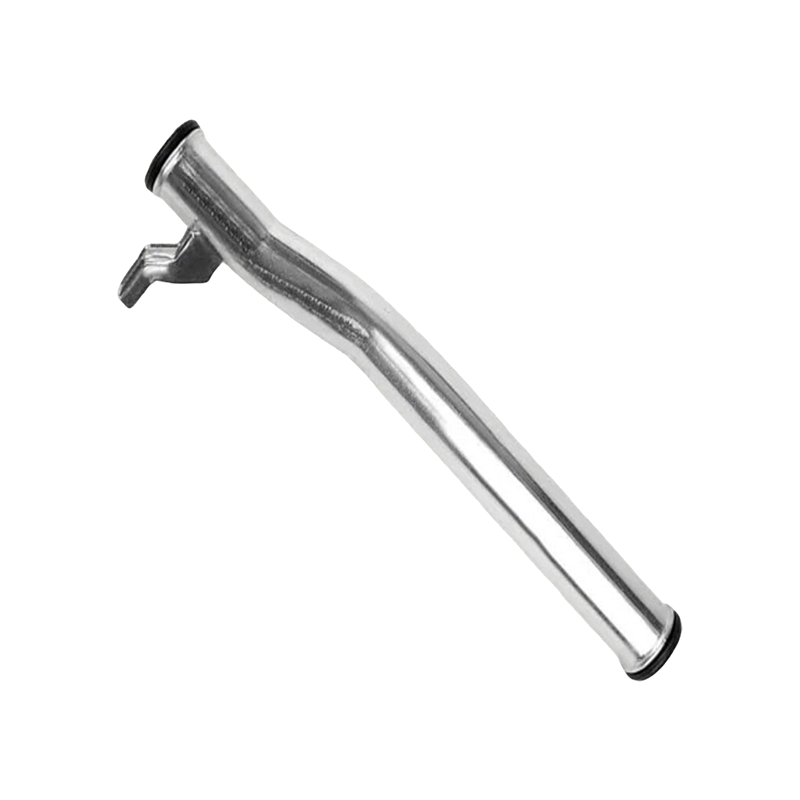

- EGR Pipe (or Tube): This is the conduit, the pathway that physically connects the exhaust system to the intake manifold. It's responsible for safely transporting the hot, soot-laden exhaust gases from one point to the other.

- Sensors and Actuators: Various sensors, like position sensors on the EGR valve and temperature/pressure sensors in the intake, provide feedback to the ECU to ensure the system is functioning as intended.

While the EGR valve often gets the most attention, the EGR pipe is just as critical. If this pathway is blocked or broken, the entire system's purpose is defeated.

The Unsung Hero: The Role of the EGR Tube Assembly

The EGR tube, or pipe assembly, lives a tough life. It is constantly subjected to a punishing environment. On one end, it's connected to the exhaust system, where it handles gases that can be several hundred degrees hot. On the other end, it connects to the intake manifold. It must withstand rapid heating and cooling cycles, intense vibration from the engine, and the corrosive nature of exhaust byproducts.

Its function is straightforward but vital: to provide a clear, unobstructed path for exhaust gases. The design of the tube is specific to each vehicle model, with precise bends and dimensions to navigate the tight confines of the engine bay and connect perfectly to the EGR valve and intake ports.

The material used for an EGR tube is a key factor in its longevity and performance. Many original equipment manufacturers use high-grade stainless steel for this very reason. Stainless steel offers excellent resistance to heat and corrosion, which helps prevent the tube from rusting, cracking, or deteriorating over time. A durable construction ensures that the tube can maintain its structural integrity despite the harsh conditions, preventing leaks that could disrupt the engine's air-fuel ratio.

Why High-Temperature Materials Matter

The choice of material for an EGR tube is not an accident; it's a deliberate engineering decision. Standard steel or other lesser materials can warp, crack, or corrode when exposed to the extreme heat cycling of the EGR system. A crack, even a small one, can create an exhaust leak. This leak can allow unmetered air to enter the system or let exhaust gases escape where they shouldn't. Both scenarios will confuse the engine's oxygen sensors and the ECU, leading to a cascade of performance problems.

Furthermore, corrosion on the inside of the tube can create a rough surface, making it easier for carbon deposits to stick and build up, eventually leading to a blockage. A high-temperature stainless steel replacement part, like the OE E9SZ9D477B EGR Tube Assembly - High-Temperature Stainless Steel Replacement Part, is designed to resist these issues. Its construction is aimed at providing a long-lasting, reliable solution that can handle the thermal stress and corrosive environment, helping to ensure the EGR system functions correctly for an extended period.

Warning Signs: Symptoms of a Malfunctioning EGR Pipe

When an EGR pipe begins to fail, it will typically present a set of recognizable symptoms. Being able to identify these signs can help you diagnose the problem early and prevent further damage to your engine or emissions system. Here are some of the common indicators:

1. The Check Engine Light is On

This is often the first and most obvious sign. The engine control unit (ECU) constantly monitors the EGR system. It uses sensors to track the EGR valve's position and the flow of exhaust gases. If the ECU commands the valve to open but doesn't see the expected change in pressure or flow, it will log a fault code. Common codes related to EGR flow issues include P0401 (Exhaust Gas Recirculation Flow Insufficient) or P0402 (Exhaust Gas Recirculation Flow Excessive). A blocked or leaking EGR pipe is a frequent cause of a "flow insufficient" code.

2. Rough Idle or Engine Stalling

A properly functioning EGR system is designed to be inactive at idle. The EGR valve should be closed, preventing any exhaust gas from entering the intake. However, if the EGR pipe is clogged with carbon, the valve may not be able to close fully. This can allow a small, uncontrolled amount of exhaust gas to leak into the intake at idle, disrupting the delicate air-fuel mixture needed for a smooth idle. This can result in a rough, shaking feeling when the car is stopped, and in severe cases, it can cause the engine to stall.

3. Reduced Engine Performance and Hesitation

If the EGR pipe is partially or fully blocked, the EGR system will be unable to function when it's supposed to—typically during cruising or light acceleration. While this might seem like it would increase performance, it can actually have the opposite effect. The ECU expects the EGR system to be active and may adjust fuel and timing based on that assumption. When the expected flow doesn't happen, it can lead to poor combustion, resulting in a noticeable lack of power, hesitation on acceleration, or a feeling that the engine is "lagging."

4. Engine Knocking or Pinging

This symptom is more direct. If the EGR pipe is blocked and the EGR system cannot introduce inert exhaust gas to cool the combustion chamber, temperatures can rise excessively, especially under load. This high temperature can cause the air-fuel mixture to ignite prematurely or unevenly, creating a metallic "pinging" or "knocking" sound. This is not only bad for performance but can also cause long-term damage to pistons and other engine components if left unchecked.

5. Failed Emissions Test

The entire purpose of the EGR system is to reduce NOx emissions. If the pipe is faulty and the system is inoperative, your vehicle will almost certainly produce elevated levels of NOx. This will lead to a failure during any mandatory emissions testing, as the pollutants will be well above the legal limits.

6. Poor Fuel Economy

When the EGR system isn't working correctly, the engine's combustion process is less efficient. The ECU may try to compensate for the incorrect air-fuel mixture or abnormal combustion temperatures by adjusting fuel injection and ignition timing. This compensation often results in the engine burning more fuel than necessary to produce the same amount of power, leading to a noticeable drop in miles per gallon.

To help you visualize these issues, here is a table summarizing the symptoms and their direct causes related to the EGR pipe:

| Symptom | How the EGR Pipe Causes It |

|---|---|

| Check Engine Light (Code P0401) | The ECU detects insufficient exhaust gas flow due to a blockage in the pipe. |

| Rough Idle / Stalling | Carbon buildup prevents the EGR valve from closing fully, allowing exhaust gas into the intake at idle. |

| Reduced Performance / Hesitation | A blocked pipe prevents the EGR system from operating during cruising, leading to inefficient combustion. |

| Engine Knocking (Detonation) | Lack of EGR flow allows combustion chamber temperatures to rise too high, causing premature ignition. |

| Failed Emissions Test | An inoperative EGR system leads to excessively high NOx output. |

| Poor Fuel Economy | The ECU compensates for incorrect combustion conditions, often by enriching the fuel mixture. |

Root Causes: Why Do EGR Pipes Fail?

Understanding the "why" behind a failure can often help with prevention. EGR pipes don't typically fail without a reason. The two primary causes of EGR pipe malfunction are carbon buildup and physical degradation.

Carbon Deposits: The Silent Blocker

This is the most common cause of EGR pipe failure. Exhaust gas is not clean; it contains a significant amount of unburnt hydrocarbons, soot, and other particulates. As this hot gas travels through the EGR pipe, these particles cool and stick to the inner walls of the tube. Over thousands of miles, this buildup accumulates layer by layer, much like plaque in an artery.

Eventually, this carbon buildup can become so thick that it severely restricts or even completely blocks the passage of exhaust gas. The pipe becomes clogged, and the EGR system is rendered useless. This is a gradual process, which is why the symptoms may appear slowly and worsen over time.

Physical Damage and Corrosion

The second major cause of failure is physical breakdown of the pipe itself. This can manifest in a few ways:

- Cracks and Holes: The extreme heat cycling (going from cold to hundreds of degrees and back again) puts immense thermal stress on the metal. Over time, this can cause the material to become brittle and develop cracks. Engine vibration can also contribute to metal fatigue, leading to cracks, especially at weld points or bends. A crack or hole creates an exhaust leak.

- Corrosion and Rust: If the pipe is made from a material that is not sufficiently corrosion-resistant, it can rust from the inside out due to the corrosive nature of exhaust gases. External corrosion can also occur from exposure to road salt and moisture. Rust weakens the metal, making it more susceptible to cracking and developing holes.

- Failed Gaskets or Connections: Sometimes the pipe itself is fine, but the gaskets or seals at the connection points (where it bolts to the exhaust manifold, EGR valve, or intake manifold) fail. A failed gasket can act just like a crack in the pipe, creating a leak and disrupting system function.

The Solution: Choosing and Installing a Quality Replacement

Once a faulty EGR pipe is diagnosed, the solution is replacement. While some might attempt to clean a clogged pipe, this is often a temporary fix. The cleaning process may not remove all the carbon, and it can also damage the pipe. Furthermore, if the pipe is clogged, it's a sign that it has seen a lot of wear, and the underlying metal may be weakened or corroded. A replacement provides a more reliable and long-term solution.

When selecting a replacement part, it's important to consider a few key factors to ensure a proper fit and dependable performance.

Material and Construction

As discussed earlier, the material is a critical consideration. Opting for a replacement made from high-temperature stainless steel is a wise choice. This material offers the resistance needed to combat the heat and corrosion that caused the original part to fail. A well-constructed part will have smooth bends for good flow and high-quality welds that are less prone to cracking.

This table compares common materials used for EGR tubes to highlight the benefits of a stainless steel construction:

| Material | Heat Resistance | Corrosion Resistance | Typical Lifespan |

|---|---|---|---|

| Aluminized Steel | Good, but can degrade over time | Fair; coating can be scratched, leading to rust | Moderate |

| Standard Mild Steel | Adequate, but prone to warping | Poor; rusts easily from inside and out | Shorter |

| High-Temp Stainless Steel | Excellent; resists warping and fatigue | Excellent; highly resistant to rust and corrosion | Longer |

Fit and Form

A replacement EGR tube must be designed to match the original equipment specifications. This means the length, diameter, and bend angles must be identical to the original part. A direct-fit replacement ensures that it will bolt up perfectly to the EGR valve and intake manifold without any need for modification, bending, or stretching. Using a part that doesn't fit correctly can lead to leaks, stress on other components, and premature failure of the new part.

Professional Installation vs. DIY

Replacing an EGR tube can range from a relatively simple job to a very challenging one, depending entirely on the vehicle's make and model. On some vehicles, the EGR pipe is easily accessible in the engine bay. On others, it is buried deep under other components, making it difficult to even see, let alone reach with tools.

The process generally involves: 1. Locating the EGR tube and valve. 2. Disconnecting any electrical connectors from the EGR valve. 3. Carefully removing the bolts that hold the pipe to the exhaust and intake sides. These bolts are often prone to seizing or breaking due to the heat, so penetrating oil and patience are required. 4. Removing the old pipe and gaskets. 5. Cleaning the mounting surfaces on the manifold and valve. 6. Installing the new pipe with new gaskets and torquing the bolts to the manufacturer's specifications. 7. Reconnecting any electrical components. 8. Starting the engine and checking for leaks. 9. Using a scan tool to clear the EGR-related fault codes from the ECU.

If you are not comfortable with this type of work, or if the pipe is in a difficult-to-reach location, it is highly recommended to have a professional mechanic perform the replacement. A professional will have the experience and tools necessary to handle seized bolts and ensure the job is done correctly, preventing future issues.

Proactive Steps for a Healthier EGR System

While EGR pipe failure is often considered a normal wear-and-tear item, there are a few things you can do as a vehicle owner to help promote the longevity of the entire EGR system and potentially extend the life of its components.

- Use Quality Fuel and Oil: High-quality fuels and motor oils tend to burn cleaner, producing fewer byproducts that can contribute to carbon buildup in the EGR system.

- Keep Up with Regular Maintenance: Regular oil changes and air filter replacements ensure your engine is running as efficiently as possible, which can reduce the amount of unburnt fuel and soot in the exhaust.

- Avoid Frequent Short Trips: Short trips where the engine never fully reaches operating temperature can promote carbon buildup. Occasionally taking your vehicle on a longer drive that allows the engine to get hot and run for a sustained period can help burn off some of the lighter deposits.

Conclusion: A Small Part with a Big Impact

The EGR pipe may be just one small tube in the complex anatomy of your vehicle, but its role is undeniably important. It is the critical pathway that enables the EGR system to control emissions, manage engine temperature, and maintain performance. When this pipe becomes clogged or damaged, it sets off a chain reaction of problems, from a simple check engine light to significant performance loss and increased emissions.

Recognizing the symptoms of a failing EGR pipe is the first step toward resolving the issue. By understanding the causes of its failure and the importance of choosing a well-constructed, direct-fit replacement part, you can make an informed decision that restores your vehicle to proper working order. A high-quality replacement, designed to withstand the harsh environment of the engine bay, is an investment in your vehicle's health, performance, and cleanliness for the road ahead.

Content

- 1 Understanding the EGR System: A Simple Explanation

- 2 The Unsung Hero: The Role of the EGR Tube Assembly

- 3 Warning Signs: Symptoms of a Malfunctioning EGR Pipe

- 4 Root Causes: Why Do EGR Pipes Fail?

- 5 The Solution: Choosing and Installing a Quality Replacement

- 6 Proactive Steps for a Healthier EGR System

- 7 Conclusion: A Small Part with a Big Impact

Our Main Products

Contact Us

Contact Us

+86-138 0586 3066

+86-574 8840 6311

Send An E-mail

Send An E-mail

Mobile

Mobile

Copyright ?NINGBO JIATIAN AUTOMOBILE PIPE CO.,LTD. All Rights Reserved.

English

English Espa?ol

Espa?ol