Industry News

Is Your Diesel Engine Losing Power? A Closer Look at Fuel Delivery Issues

Is Your Diesel Engine Losing Power? A Closer Look at Fuel Delivery Issues

If you've noticed your diesel vehicle, truck, or equipment isn't responding the way it used to, you're not alone. A gradual loss of power, a rough idle, or a sudden decrease in fuel economy can be frustrating and concerning. While many potential culprits exist, from turbochargers to sensors, one of the fundamental systems to scrutinize is the high-pressure fuel delivery system. This network of components is the lifeblood of a modern diesel engine, and a weakness anywhere in its chain can have a significant impact on performance, efficiency, and safety.

This article serves as a comprehensive guide to understanding one of the more common, yet sometimes overlooked, points of failure in this system: the high-pressure fuel injector line. We will explore the role these lines play, how they fail, the symptoms to watch for, and why choosing a high-quality replacement component is a decision that pays dividends in reliability and peace of mind. We will demystify the complexities of diesel injection in plain language, empowering you to make informed decisions about maintaining your vehicle's health.

The Heart of the Matter: Understanding High-Pressure Diesel Injection

To appreciate why a single metal line can be so important, we first need to understand the environment in which it operates. Modern diesel engines are marvels of engineering, designed to be powerful, efficient, and relatively clean. A key part of this achievement is the high-pressure common-rail injection system (or its close relatives). Unlike older diesel systems that relied on lower pressures and mechanical timing, today's engines pressurize fuel to astonishing levels—often exceeding 20,000 pounds per square inch (psi)—before it's ever injected into the combustion chamber.

Why such extreme pressure? The answer lies in the physics of combustion. Forcing fuel into the cylinder through a tiny injector nozzle at such high pressure creates a very fine, atomized mist. This mist has a large surface area, allowing it to mix more thoroughly and quickly with the compressed, hot air in the cylinder. The result is a more complete and controlled burn, which translates directly into more power, better fuel economy, and reduced emissions. The entire system, from the high-pressure pump to the injectors themselves, is designed to contain and control these immense forces.

The Journey of Fuel: From Tank to Combustion

Let's trace the path of diesel fuel to see where the injector line fits into the bigger picture:

- Low-Pressure Stage: Your journey begins in the fuel tank. An initial lift pump (or low-pressure fuel pump) draws fuel from the tank and sends it through a pre-filter and a primary fuel filter. This stage is about getting a clean, consistent supply of fuel to the main event.

- The High-Pressure Pump: The filtered, low-pressure fuel then enters the high-pressure fuel pump. This is the muscle of the system. Driven by the engine, this pump rapidly pressurizes the fuel, sending it into the "common rail"—a sturdy manifold (or a single pipe in simpler systems) that acts as an accumulator, holding the fuel at a constant, very high pressure, ready for deployment.

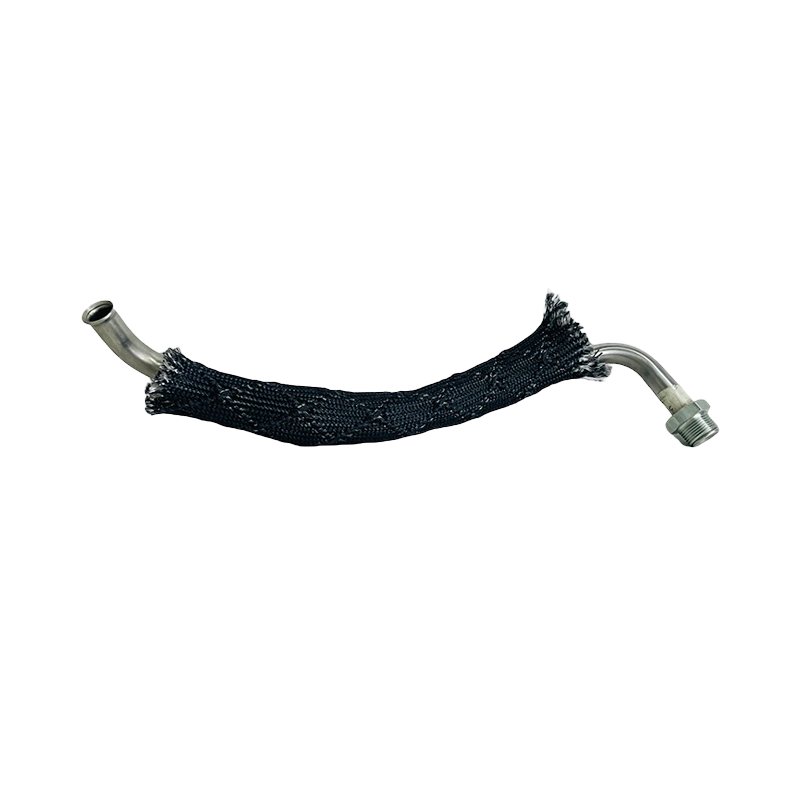

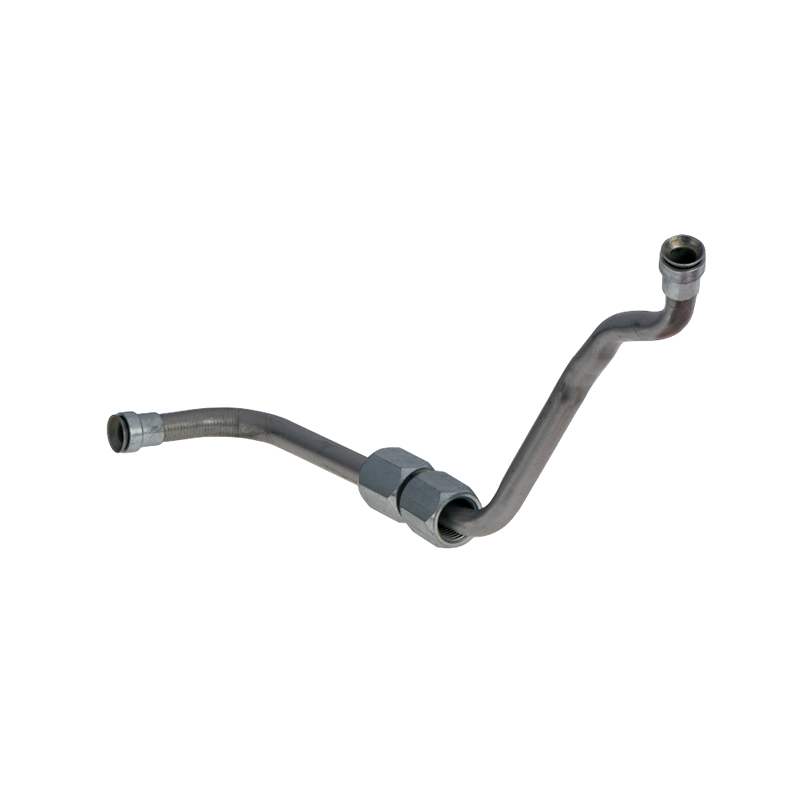

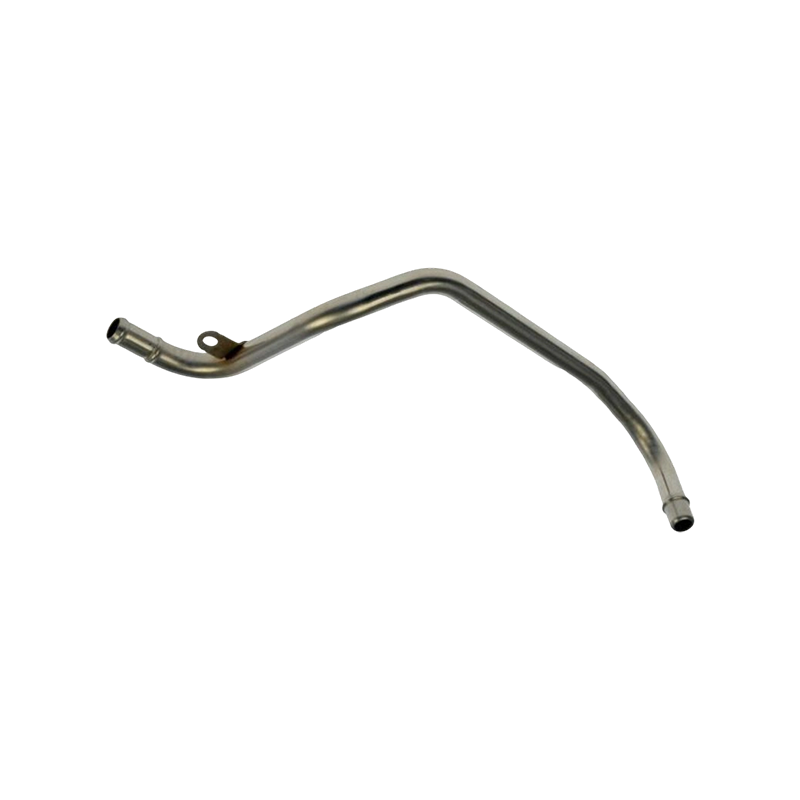

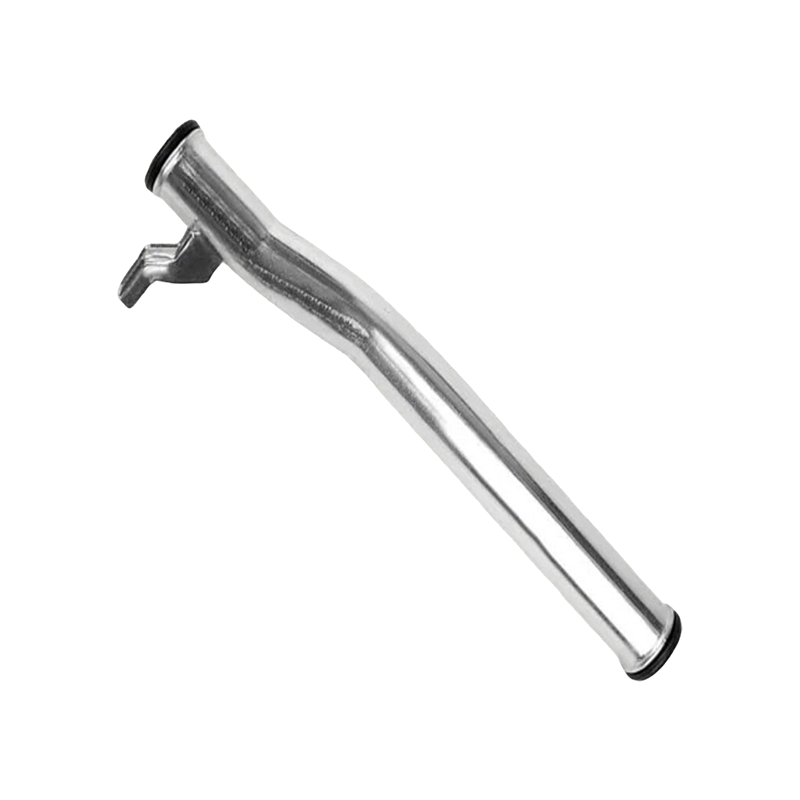

- The Injector Lines: This is our area of focus. From the common rail (or directly from the pump in some designs), individual high-pressure lines transport the pressurized fuel to each fuel injector. These lines are not just simple tubes; they are precisely engineered conduits designed to handle intense pressure and vibration without leaking or failing.

- The Fuel Injectors: At the end of each line is a fuel injector. These are incredibly fast and precise valves, controlled by the engine's computer (ECU). At the exact millisecond required, the ECU commands the injector to open, allowing a precisely measured burst of atomized fuel to spray into the cylinder.

- Combustion and Power: The finely atomized fuel ignites from the heat of the compressed air, pushing the piston down and creating the power that drives your vehicle.

As you can see, the fuel injector line is a critical link in this high-stakes chain. It is the final bridge for the fuel on its journey to being converted into power. Any compromise in this link disrupts the entire process.

The Unsung Hero: The Critical Role of the Fuel Injector Line

A fuel injector line might look like a simple piece of bent metal tubing, but its reality is far more complex. It is a high-performance component that must meet several demanding requirements simultaneously:

- Immense Pressure Containment: The primary function is to contain fuel at pressures that can cut through steel. The walls of the tube must be thick enough and made of a material strong enough to handle this constant internal force without bulging, cracking, or bursting.

- Vibration Resistance: An engine is a constantly vibrating machine. The injector line is rigidly mounted at both ends, connecting the vibrating engine block to the vibrating cylinder head. It is subjected to constant flexing and harmonic vibrations. Over time, this can lead to metal fatigue, much like bending a paperclip back and forth.

- Precision Fitment: The ends of the line are not simple slip-fit connections. They use specialized, high-pressure flare fittings (often banjo fittings or conical seals) that must mate perfectly with the ports on the rail and the injector. Even a microscopic imperfection on the sealing surface can lead to a high-pressure leak.

- Corrosion Resistance: These lines are exposed to the elements: road salt, moisture, oil, and grime. A quality line is made from corrosion-resistant steel or has a protective coating to prevent rust from weakening the tube, especially at the fittings where it matters most.

When a line is functioning as intended, it's completely invisible to the driver. It does its job silently and reliably. But when it begins to fail, it announces its problem in several noticeable, and sometimes dangerous, ways.

How to Spot a Failing Fuel Injector Line: Key Symptoms

Recognizing the signs of a failing injector line early can prevent more extensive and expensive damage. Here are the common symptoms to be aware of, ranging from subtle to severe:

1. The Obvious Sign: Fuel Smell and Visible Leaks

This is the most direct indicator. A high-pressure leak in a diesel fuel line is not a slow drip; it's often a fine, atomized spray of fuel that can be difficult to see but easy to smell. You may notice a strong, persistent odor of diesel fuel inside the cabin or around the engine bay, especially after the engine has been running and is under pressure. In some cases, you might see wetness around the fittings or along the length of the line. Any fuel leak is a serious safety hazard and should be addressed immediately.

2. Performance Issues: Loss of Power and Rough Running

A leak means that not all the pressurized fuel is reaching the injector. The cylinder fed by that faulty line will receive less fuel than it needs, leading to an imbalance in power delivery across all cylinders. This can manifest as:

- A noticeable loss of overall engine power and acceleration.

- A rough or unstable idle, where the engine feels like it's stumbling or shaking.

- Engine misfiring or hesitation, particularly under load (like going up a hill or accelerating hard).

3. Hard Starting or No-Start Conditions

The fuel system needs to prime and build pressure before the engine can start. If there is a significant leak, the system may be unable to build the required pressure. You might find that the engine cranks for a long time before it finally catches, or in severe cases, it won't start at all.

4. Poor Fuel Economy

If fuel is leaking out, it's not being used for combustion. You are literally pouring money onto the ground. Even a small, high-pressure mist leak can waste a surprising amount of fuel over time, leading to a noticeable drop in your miles per gallon.

5. Illuminated Check Engine Light

Modern engine computers are smart. The ECU monitors the fuel system through various sensors. If it detects a problem like a fuel rail pressure that is too low (because of a leak), it will log a trouble code and illuminate the "Check Engine" light on your dashboard. Common codes might relate to "Fuel Rail Pressure Too Low" or "Cylinder Contribution/Balance Fault."

The Dangers of Ignoring a Leaking Fuel Line

It might be tempting to ignore a small fuel smell or a minor power loss, especially if the vehicle still runs. This is a risky proposition. The consequences of a failing injector line go far beyond poor performance.

Fire Hazard: This is the most significant danger. The fuel leaking from a high-pressure line is not in liquid form; it's an aerosol—a fine mist of highly flammable particles suspended in the air. This mist can travel far from the leak itself and can be ignited by a hot engine component, an electrical spark, or even the heat of the exhaust manifold. A diesel fuel fire is extremely difficult to extinguish and can lead to the total destruction of the vehicle.

Catastrophic Engine Damage: A sudden, catastrophic failure of the line (a burst) can dump a large amount of fuel into the engine bay. More critically, the sudden loss of pressure can cause the high-pressure fuel pump to run dry or draw in air, which can damage the pump itself. Furthermore, if the ECU continues to command injectors to open while the system pressure is unstable, it can lead to injector damage. Replacing a high-pressure pump or a set of injectors is a vastly more expensive repair than replacing a single fuel line.

Environmental Contamination: Leaking diesel fuel contaminates soil and groundwater. It is harmful to the environment and, in many places, illegal. Being a responsible vehicle owner includes ensuring your vehicle isn't polluting.

The Right Replacement: Why Quality Matters

Once you've identified a faulty injector line, the next step is replacement. This is where a critical decision is made. The market is flooded with parts of varying quality, and when it comes to a high-pressure fuel system, the adage "you get what you pay for" is very relevant. Choosing a low-quality, uncertified replacement part can be as dangerous as leaving the faulty line in place.

A replacement line must meet or exceed the original equipment (OE) specifications in every way: material strength, dimensional accuracy, fitting precision, and corrosion resistance. A line that doesn't fit correctly can put stress on the injector or rail fittings during installation, leading to premature failure. A line made from inferior steel may not be able to handle the pressure, leading to a burst. A line with poorly machined fittings will inevitably leak.

This is where a component like the Maintain Peak Engine Performance with a Precision Fuel Injector Line (OE# 98063063) becomes a key consideration. Such components are engineered specifically to be direct-fit replacements, designed with the original specifications in mind. This ensures that the part will fit correctly without modification, function reliably under pressure, and provide the long-term durability required for a critical engine component. The goal of a quality replacement is not just to fix the immediate problem, but to restore the fuel system to its intended state of safe and reliable operation.

What to Look For in a Quality Fuel Line

To help you make an informed choice, consider the following comparison of features. This table highlights the differences between a well-engineered component and a lower-quality alternative.

| Feature | High-Quality Replacement Line | Low-Quality Alternative |

|---|---|---|

| Material Composition | High-grade steel, often with corrosion-resistant coatings (e.g., zinc or dacromet). Material is certified for strength and durability. | Unknown or low-grade steel. May lack proper coating, making it susceptible to rust and weakening. |

| Dimensional Accuracy | Precisely bent to match the OE routing, ensuring no stress on fittings. Correct inner and outer diameter for proper flow and pressure. | Inconsistent bends; may require forcing into place, which can damage mounting points or the line itself. Diameter may be incorrect. |

| Fitting Machining | Connectors and flares are machined to tight tolerances for a perfect, leak-free seal against the injector and rail. | Roughly finished fittings. Poor sealing surfaces that are likely to weep or spray high-pressure fuel, even when torqued correctly. |

| Pressure Rating | Tested and rated to meet or exceed the vehicle's OE fuel system pressure specifications. | Pressure rating is often unknown, untested, or not provided, posing a significant risk of failure under operating conditions. |

| Fitment and Installation | Designed as a direct-fit, bolt-on replacement. No modifications, bending, or special adapters are needed. | May require adjustments, bending, or creative installation, which compromises safety and reliability. |

Installation: More Than Just Wrenching

Even with the highest quality part, proper installation is crucial for success and safety. Replacing a high-pressure fuel line is a job that requires care, attention to detail, and the right approach. While it can be a DIY project for those with significant mechanical experience, it's often best left to a qualified technician.

Safety First: Before beginning, the vehicle's battery should be disconnected to prevent any accidental sparks. It's also wise to relieve the fuel system pressure, though some pressure will remain. Safety glasses and gloves are mandatory.

Cleanliness is Key: The area around the fittings on the injector and the rail must be meticulously cleaned before disassembly. Any dirt or debris that falls into an open fuel port can travel downstream and destroy sensitive internal components like the injector or the high-pressure pump.

Use the Correct Tools: The fittings on these lines often require specific flare-nut wrenches (or line wrenches). These wrenches grip more of the nut than a standard open-end wrench, reducing the chance of rounding off the fitting. Never use pliers or an adjustable wrench.

Tightening to Specification: This is one of the most critical steps. The fittings must be tightened to the manufacturer's specified torque. Overtightening is just as bad as undertightening. Overtightening can crush the sealing surface, distorting the metal and creating a leak path. It can also damage the threads on the injector or rail, leading to a very expensive repair. Undertightening will obviously result in a leak. A torque wrench is an essential tool for this job.

Final Checks: After installation, with the battery reconnected, cycle the key to the "on" position a few times without starting the engine to allow the fuel pump to prime the system and build pressure. Carefully inspect the new line and its fittings for any signs of weeping. Once you are confident there are no leaks, start the engine and let it idle, checking again for leaks before taking the vehicle for a test drive.

Proactive Maintenance: Protecting Your Fuel System

While components like fuel injector lines can fail due to age and vibration, you can take steps to promote the longevity of your entire fuel system.

- Use Quality Fuel: Purchase diesel from reputable, high-volume stations. This reduces the risk of getting contaminated or poor-quality fuel that can damage injectors and pumps.

- Replace Filters Regularly: Your fuel filters are the first line of defense against water and particulate contamination. Adhering to the manufacturer's recommended replacement interval is one of the best things you can do for the health of your fuel system.

- Visual Inspections: Periodically, take a look in your engine bay. Look for any signs of wetness, corrosion, or damage to the fuel lines and other components. Catching a small issue early can prevent a big problem later.

- Don't Ignore Warning Signs: If you notice a change in how your engine runs, a new smell, or a warning light, don't wait. Investigate the issue promptly. Addressing small problems is always less costly and safer than dealing with catastrophic failures.

Conclusion: An Investment in Performance and Safety

The high-pressure fuel injector line is a small component with a very big responsibility. It operates in one of the harshest environments within your engine, and its failure can have consequences ranging from poor drivability to a dangerous vehicle fire. Understanding its role and recognizing the symptoms of its failure is a vital part of responsible diesel engine ownership.

When replacement becomes necessary, the choice of component is paramount. Opting for a precision-engineered part that adheres to OE specifications is not just about restoring lost power; it's about restoring the integrity and safety of your vehicle's fuel system. It's an investment in reliability, performance, and your own peace of mind. By choosing quality parts and ensuring proper installation, you can keep your diesel engine running smoothly, efficiently, and safely for miles to come, ensuring it continues to deliver the power and dependability you rely on every day.

Content

- 1 The Heart of the Matter: Understanding High-Pressure Diesel Injection

- 2 The Unsung Hero: The Critical Role of the Fuel Injector Line

- 3 How to Spot a Failing Fuel Injector Line: Key Symptoms

- 4 The Dangers of Ignoring a Leaking Fuel Line

- 5 The Right Replacement: Why Quality Matters

- 6 Installation: More Than Just Wrenching

- 7 Proactive Maintenance: Protecting Your Fuel System

- 8 Conclusion: An Investment in Performance and Safety

Our Main Products

Contact Us

Contact Us

+86-138 0586 3066

+86-574 8840 6311

Send An E-mail

Send An E-mail

Mobile

Mobile

Copyright ?NINGBO JIATIAN AUTOMOBILE PIPE CO.,LTD. All Rights Reserved.

English

English