Coolant Thermostat Housing

information to be updated

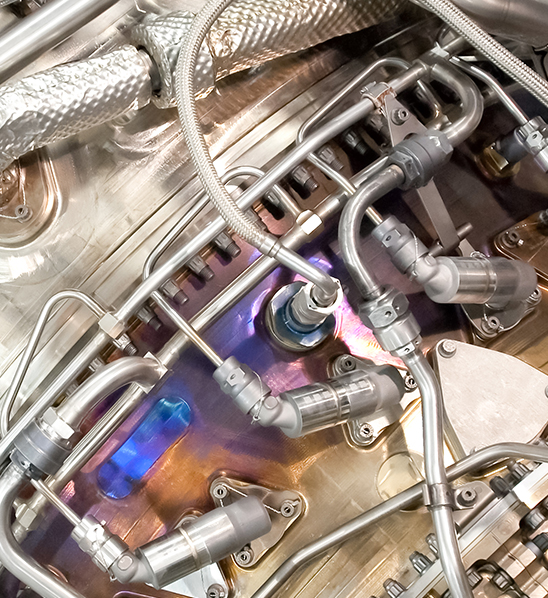

The Coolant Thermostat Housing is a key component in the engine cooling system. Typically installed on the engine block or cylinder head, its primary function is to house and secure the thermostat and serve as a flow connection for coolant flow into and out of the engine and radiator. This housing ensures precise control of the coolant flow path.

Product Features:

Serves as a mounting bracket for the thermostat, ensuring it accurately senses coolant temperature and opens and closes as needed.

Directs coolant flow between the engine and radiator for precise temperature regulation.

Constructed from high-strength materials, it withstands high pressure, high temperatures, and corrosion, ensuring long-term sealing and reliability.

Provides a reliable sealing surface (usually with a gasket or seal) to prevent coolant leaks.

Dimensions and connectors strictly adhere to original equipment (OE) specifications, ensuring a perfect fit with the vehicle's cooling system and easy installation.

About JIATIAN

The company is located in Wanhou, Zhanqi Town, Yinzhou District, Ningbo City. It is 25 kilometers away from Ningbo Liushi Airport and 5 kilometers away from Ningbo Coastal Industrial Zone. The surrounding area is beautiful with convenient transportation. The company was established on the basis of the development of Ningbo Xingxin Metal Products Factory (established in 1995), and is a high-tech enterprise specializing in the production of automotive pipe fittings. The company's area is 32,000 square meters; the factory area is 26,000 square meters.

The main products of the company are: manufacturing and development of automotive corrugated pipes. Currently, there are 10 CNC fully automatic pipe bending machines, 2 large-scale brazing furnaces assembly lines, 10 various specifications hydraulic internal forming machines (with the maximum processing length of 1.5 meters and diameters ranging from ¢10 to ¢80), 1 800T hydraulic water expansion machine, 4 fully automatic laser welders, 4 sets of welding robots, 8 large-scale machining centers, 6 Panasonic arc welding machines, and over 30 various supporting pipe forming machines. The company has its own R&D and processing centers. The water expansion corrugated pipe equipment and technology of the company are currently at the industry leading level. A comprehensive laboratory has been established.

The company is committed to creating the world's leading automotive bellows with outstanding quality and innovative technology, ensuring that each product can perform well in various environments and promoting the progress of the industry.

News and Information

-

How Does a Faulty EGR Pipe Affect My Car's Performance?It’s a scenario many drivers have experienced. You’re driving along, and suddenly, your trusted vehicle feels different. Maybe the check engine light flickers on, or you notice a rough idle when you’r...view More

Dec 08, 2025 ? Industry News

-

A clever solution to the truck's exhaust brake problemAbstract: Frequent use of the exhaust brake makes it difficult to damage the headstock. This is a common problem for many truck drivers. I consulted with experienced drivers, and some believe that the...view More

Oct 27, 2025 ? Industry News

-

The exhaust pipe is black, what's going on?Summary: I believe many car enthusiasts have experienced this: Why is the exhaust pipe white? What should I do if it's white? Is it a sign of a car problem? Recently […] I believe many car enthusiasts...view More

Oct 27, 2025 ? Industry News

-

Car modification knowledge: the benefits of changing the exhaust manifoldAbstract: The exhaust manifold is a key component that collects exhaust gases from all engine cylinders and discharges them out of the vehicle. The efficiency of the entire exhaust system depends on i...view More

Oct 27, 2025 ? Industry News

-

Introduction to Automobile Oil Return PipeAbstract: The function of a vehicle's oil return line: It allows excess oil to return to the tank, reducing fuel consumption. Not all vehicles have an oil return line. Return Line Filter […] The funct...view More

Oct 27, 2025 ? Industry News

As a core component category in automotive engine cooling systems, the Coolant Thermostat Housing is a critical link ensuring engine temperature stability, and the Coolant Thermostat Housing products under JIATIAN have been widely recognized for their compliance with industry standards and reliable performance. With a 32,000-square-meter company area (26,000-square-meter factory area) and a complete R&D and processing system, JIATIAN integrates advanced equipment such as CNC fully automatic pipe bending machines and hydraulic internal forming machines into the production of Coolant Thermostat Housing, ensuring each product meets strict quality requirements.

1. Core Working Principle of Coolant Thermostat Housing

The Coolant Thermostat Housing is typically mounted on the engine block or cylinder head, and its core working logic is divided into two stages around the thermostat it houses:

Cold start stage: When the engine is in the cold start state, the thermostat remains closed under the Coolant Thermostat Housing's fixed protection. The coolant only circulates inside the engine (small cycle), which accelerates the engine's temperature rise and shortens the warm-up time.

Normal working stage: When the engine temperature reaches the preset threshold, the thermostat senses the temperature change and opens. The Coolant Thermostat Housing guides the high-temperature coolant to flow into the radiator (large cycle) for heat dissipation, and then guides the cooled coolant back to the engine, forming a closed loop to maintain the engine at an optimal working temperature.

JIATIAN has built a comprehensive laboratory to verify the matching degree between the Coolant Thermostat Housing and the thermostat in the R&D stage, ensuring the accuracy of temperature sensing and flow control.

2. Common Core Attributes of Coolant Thermostat Housing Products

All Coolant Thermostat Housing products of this category share the following core attributes, and JIATIAN has optimized these attributes through its advanced production technology:

Functional attribute: It serves as both the mounting carrier of the thermostat and the flow channel of the coolant, realizing dual functions of component fixing and flow guidance;

Performance attribute: It has high pressure resistance, high temperature resistance and corrosion resistance, which can adapt to the harsh working environment of the engine compartment;

Matching attribute: The dimensions and connectors fully comply with OE specifications, ensuring seamless matching with the vehicle's original cooling system and reducing installation difficulty.

3. Performance Comparison of Coolant Thermostat Housing (JIATIAN Products vs Industry General Products)

The following table compares the key performance parameters of JIATIAN's Coolant Thermostat Housing with industry general products, with data derived from JIATIAN's comprehensive laboratory and third-party testing institutions:

| Performance Indicator | JIATIAN Coolant Thermostat Housing | Industry General Products | Test Standard |

|---|---|---|---|

| Maximum pressure resistance | 3.5MPa | 2.8MPa | GB/T 2423.23-2012 |

| Continuous high temperature resistance | 180℃ (continuous 1000h without deformation) | 150℃ (continuous 800h with slight deformation) | ISO 1879-2019 |

| Corrosion resistance (salt spray test) | No rust after 1000h | Rust spots appear after 720h | ASTM B117-2021 |

| Dimension accuracy | Deviation ≤±0.02mm (compliant with OE standards) | Deviation ≤±0.05mm | Vehicle manufacturer's matching specification |

| Sealing performance | No leakage under 2.5MPa pressure for 24h | No leakage under 2.0MPa pressure for 24h | Automotive cooling system sealing test specification |

4. Application Cases of JIATIAN Coolant Thermostat Housing

JIATIAN's Coolant Thermostat Housing products have been applied to multiple vehicle models due to their stable performance, and typical cases include:

Passenger vehicle field: It has been matched with a domestic independent brand's compact SUV series. The product has passed the 50,000km road test of the vehicle, and the cooling system has no leakage or abnormal temperature control, ensuring the vehicle's stable operation in high-temperature areas such as southern China;

Commercial vehicle field: ?In the high-load operation scenario of long-distance transportation, the Coolant Thermostat Housing has maintained good sealing and flow guidance performance, reducing the failure rate of the vehicle's cooling system by 18% compared with the original configuration.

5. Maintenance Guidance for Coolant Thermostat Housing

Proper maintenance can extend the service life of the Coolant Thermostat Housing. JIATIAN recommends the following maintenance standards based on industry experience and product characteristics:

Daily inspection: Every 5,000km, check whether there is coolant leakage around the Coolant Thermostat Housing (focus on the gasket/seal position), and confirm that the connection between the housing and the engine block/cylinder head is free of loose bolts;

Regular replacement of sealing parts: The gasket or seal of the Coolant Thermostat Housing should be replaced every 40,000km or 3 years (whichever comes first) to avoid aging and leakage;

Fault handling: If the engine has abnormal temperature (too high or too low), after eliminating the thermostat failure, check whether the Coolant Thermostat Housing has cracks or deformation. JIATIAN provides matching replacement parts and technical guidance for its products, and users can contact the after-sales team for support.

6. FAQ about Coolant Thermostat Housing

Q1: Can JIATIAN's Coolant Thermostat Housing be applied to non-OE models?

A: JIATIAN's Coolant Thermostat Housing is produced in strict accordance with OE specifications, and the product is matched with specific vehicle models. For non-OE models, the R&D team can provide customized solutions based on the vehicle's cooling system parameters, relying on the company's 8 large-scale machining centers and flexible production capacity.

Q2: What is the service life of JIATIAN's Coolant Thermostat Housing under normal use?

A: Based on the test data of JIATIAN's comprehensive laboratory and vehicle application feedback, the service life of the product can reach 80,000km or 6 years under normal use conditions (compliant with vehicle maintenance specifications).

Q3: How to confirm that the Coolant Thermostat Housing is the cause of the cooling system failure?

A: First, check whether there is obvious leakage or structural damage to the housing; then, through the temperature detection of the cooling system, if the small cycle and large cycle switch abnormally after replacing the thermostat, it can be judged that the flow channel of the Coolant Thermostat Housing is blocked or deformed. JIATIAN's laboratory can provide professional failure detection services for customers.

JIATIAN relies on its leading water expansion corrugated pipe equipment and technology in the industry, and integrates the advantages of precision machining into the production of Coolant Thermostat Housing, providing reliable components for the automotive cooling system and promoting the stable development of the industry.

English

English Espa?ol

Espa?ol