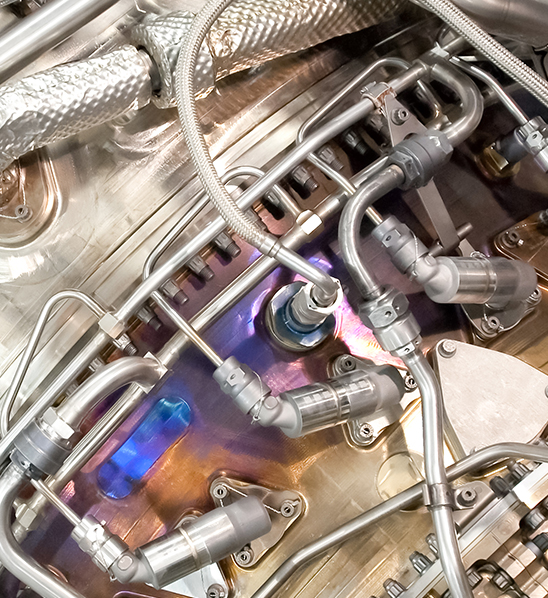

Engine Oil Cooler Hose Assembly

The Engine Oil Cooler Hose Assembly is a complete hose system used to transport engine oil to and from the oil cooler. Comprised of oil- and temperature-resistant hoses, clamps, fittings, and seals, it directly replaces original equipment parts, ensuring reliable oil circulation between the cooler and the engine, preventing overheating and ensuring effective lubrication.

Product Features:

Designed to withstand the high oil temperatures and operating pressures found within the engine oil circulation system, it utilizes high-quality rubber, synthetic materials, or braided steel reinforcement to ensure it resists bursting and deformation under extreme operating conditions.

The hose's inner layer offers excellent oil resistance, resisting chemical attack from hot oil, lubricants, and additives, preventing material degradation and leaks.

It includes a precisely formed hose, durable rigid hose section, original equipment specification connectors, seals, and positioning brackets, ensuring a perfect fit and immediate installation at the engine and cooler interfaces, reducing installation time and the risk of leaks.

The rigid metal hose section typically features a surface treatment such as galvanizing for excellent corrosion resistance, resisting environmental moisture, salt, and dirt. Ensure that the oil circulates quickly and smoothly between the engine and the oil cooler to achieve efficient cooling effect and maintain the engine oil temperature within the optimal range

About JIATIAN

The company is located in Wanhou, Zhanqi Town, Yinzhou District, Ningbo City. It is 25 kilometers away from Ningbo Liushi Airport and 5 kilometers away from Ningbo Coastal Industrial Zone. The surrounding area is beautiful with convenient transportation. The company was established on the basis of the development of Ningbo Xingxin Metal Products Factory (established in 1995), and is a high-tech enterprise specializing in the production of automotive pipe fittings. The company's area is 32,000 square meters; the factory area is 26,000 square meters.

The main products of the company are: manufacturing and development of automotive corrugated pipes. Currently, there are 10 CNC fully automatic pipe bending machines, 2 large-scale brazing furnaces assembly lines, 10 various specifications hydraulic internal forming machines (with the maximum processing length of 1.5 meters and diameters ranging from ¢10 to ¢80), 1 800T hydraulic water expansion machine, 4 fully automatic laser welders, 4 sets of welding robots, 8 large-scale machining centers, 6 Panasonic arc welding machines, and over 30 various supporting pipe forming machines. The company has its own R&D and processing centers. The water expansion corrugated pipe equipment and technology of the company are currently at the industry leading level. A comprehensive laboratory has been established.

The company is committed to creating the world's leading automotive bellows with outstanding quality and innovative technology, ensuring that each product can perform well in various environments and promoting the progress of the industry.

News and Information

-

How Does a Faulty EGR Pipe Affect My Car's Performance?It’s a scenario many drivers have experienced. You’re driving along, and suddenly, your trusted vehicle feels different. Maybe the check engine light flickers on, or you notice a rough idle when you’r...view More

Dec 08, 2025 ? Industry News

-

A clever solution to the truck's exhaust brake problemAbstract: Frequent use of the exhaust brake makes it difficult to damage the headstock. This is a common problem for many truck drivers. I consulted with experienced drivers, and some believe that the...view More

Oct 27, 2025 ? Industry News

-

The exhaust pipe is black, what's going on?Summary: I believe many car enthusiasts have experienced this: Why is the exhaust pipe white? What should I do if it's white? Is it a sign of a car problem? Recently […] I believe many car enthusiasts...view More

Oct 27, 2025 ? Industry News

-

Car modification knowledge: the benefits of changing the exhaust manifoldAbstract: The exhaust manifold is a key component that collects exhaust gases from all engine cylinders and discharges them out of the vehicle. The efficiency of the entire exhaust system depends on i...view More

Oct 27, 2025 ? Industry News

-

Introduction to Automobile Oil Return PipeAbstract: The function of a vehicle's oil return line: It allows excess oil to return to the tank, reducing fuel consumption. Not all vehicles have an oil return line. Return Line Filter […] The funct...view More

Oct 27, 2025 ? Industry News

The?Engine Oil Cooler Hose Assembly?is a critical component of the engine lubrication system's circulation loop. This assembly is responsible for establishing a sealed oil passage between the engine and the oil cooler, facilitating the transfer of hot oil and the return of cooled oil. Its core function is to ensure oil circulates at specified pressures and flow rates, maintaining oil temperature within the engine's required operating range through heat exchange.

?

Technical Characteristics?

1. Material and Structural Characteristics

-

Resistance Properties:?The component materials possess chemical stability resistant to high temperatures, oil, and hydraulic oil additives. Common structures include an inner liner, a reinforcement layer (such as fiber or steel wire braid), and an outer cover.

-

Pressure and Temperature Ranges:?The typical operating temperature range is -40°C to above +150°C. The operating pressure is designed according to engine system requirements and can withstand system pulse pressures.

2. Engineering Compatibility Characteristics

-

Dimensions and Interfaces:?The assembly's length, bend radius, fitting types (e.g., flange, thread), and seal specifications are consistent with the original vehicle components.

-

Integrated Attachments:?The assembly integrates mounting brackets, abrasion sleeves, and other attachments to ensure a fixed routing path and clearance within the engine compartment.

3. Surface Treatment and Fluid Performance

-

Corrosion Protection:?Metal fittings and rigid tube sections undergo surface treatment processes such as electroplating to enhance resistance to environmental corrosion.

-

Flow Efficiency:?The inner wall of the tubing is smooth, and the design avoids flow dead zones to reduce flow resistance and promote heat exchange efficiency.

Structure and Function Correspondence Table

| Component | Primary Function | Technical Manifestation |

|---|---|---|

| Multi-layer Composite Hose | Convey fluid, withstand pressure and temperature | Material oil & temperature resistance data; Burst pressure value |

| Metal Rigid Tube & Fittings | Provide rigid connection and interface | Material specification (e.g., stainless steel); Interface standard (e.g., DIN/SAE) |

| Sealing Elements | Ensure sealing at connection points | Material (e.g., FKM); Operating temperature range |

| Positioning Brackets | Secure the assembly, manage vibration and displacement | Bracket material (e.g., steel, aluminum); Mounting point design |

Working Principle:?When the engine is running, the oil pump delivers hot oil. This oil is transported via the supply line of the?Engine Oil Cooler Hose Assembly?to the oil cooler. Within the cooler, the oil's heat is dissipated through exchange with a cooling medium (air or coolant). The cooled oil then returns to the engine oil pan or main gallery via the assembly's return line, completing the cooling cycle.

JIATIAN's Manufacturing Capabilities and Quality Control

JIATIAN Company is located in Wanhou, Zhanqi Town, Yinzhou District, Ningbo City. Its production base covers an area of 32,000 square meters. The company specializes in the research, development, and production of automotive pipe fittings. Its manufacturing system provides technical support for the supply of the?Engine Oil Cooler Hose Assembly.

Production and Inspection Resource Configuration:

-

Forming Equipment:?Configured with 10 CNC automatic pipe bending machines, hydraulic internal forming machines (maximum processing length 1.5 meters, diameter range ?10 to ?80), and an 800T hydraulic hydroforming machine.

-

Joining Process Equipment:?Utilizes 4 fully automatic laser welders and 4 sets of welding robots for welding operations.

-

Quality Verification System:?The company's laboratory can perform tests such as pressure resistance, impulse, salt spray corrosion, and high/low temperature cycle testing.

The hydraulic hydroforming corrugated pipe technology applied by JIATIAN falls within the scope of common industry technologies. The company's products are developed and validated based on original equipment specifications and industry standards.

Frequently Asked Questions (FAQ)

Q1: What are the common signs of failure in an Engine Oil Cooler Hose Assembly?

A:?Observable phenomena include: cracking, bulging, or oil seepage on the hose's outer surface; oil residue accumulation at metal fitting joints. Persistently high readings on the engine oil temperature gauge or abnormal drops in oil level may also be related to this assembly.

Q2: How is the compatibility of aftermarket parts with original equipment parts confirmed?

A:?Confirmation is based on: cross-referencing part numbers; physical measurement and comparison of interface dimensions and types; verification of mounting bracket positions. Suppliers with comprehensive engineering data and testing capabilities (such as JIATIAN) can ensure dimensional and functional compatibility of their products.

Q3: What types of corrosion protection treatments are available for metal fittings?

A:?Common industrial treatments include zinc electroplating, zinc-nickel alloy plating, and Dacromet coating. Different treatments vary in indicators such as salt spray test duration and wear resistance, which should be referred to in the specific product specifications.

Q4: What are the key technical points for installing this assembly?

A:?Installation key points include: ensuring all interfaces are clean and undamaged before installation; using new seals and tightening fittings to the torque specified in the instructions; ensuring the assembly is routed according to the design path without interference or friction with surrounding components.

Maintenance Inspection and Selection Reference

Maintenance Inspection Items:

-

Regular Visual Inspection:?It is recommended to inspect the hose cover for cracks, hardening, localized swelling, or oil stains during routine vehicle maintenance.

-

Systematic Inspection:?During major vehicle servicing, the tightness and sealing condition at all connection points of the assembly can be checked.

Product Selection Reference Table:

| Consideration Item | Technical Parameters and Notes |

|---|---|

| Vehicle & Engine Application | Must specify the corresponding vehicle brand, model, year, and engine code. |

| Material Specifications | Hose layer structure, reinforcement type, fitting material, seal material. |

| Performance Certification | Whether it has passed relevant tests, such as ISO 11425 (Rubber hoses for hydraulic systems - Test methods). |

| Supplier Information | Supplier's production qualifications (e.g., IATF 16949), testing capabilities, and product data completeness. |

English

English Espa?ol

Espa?ol