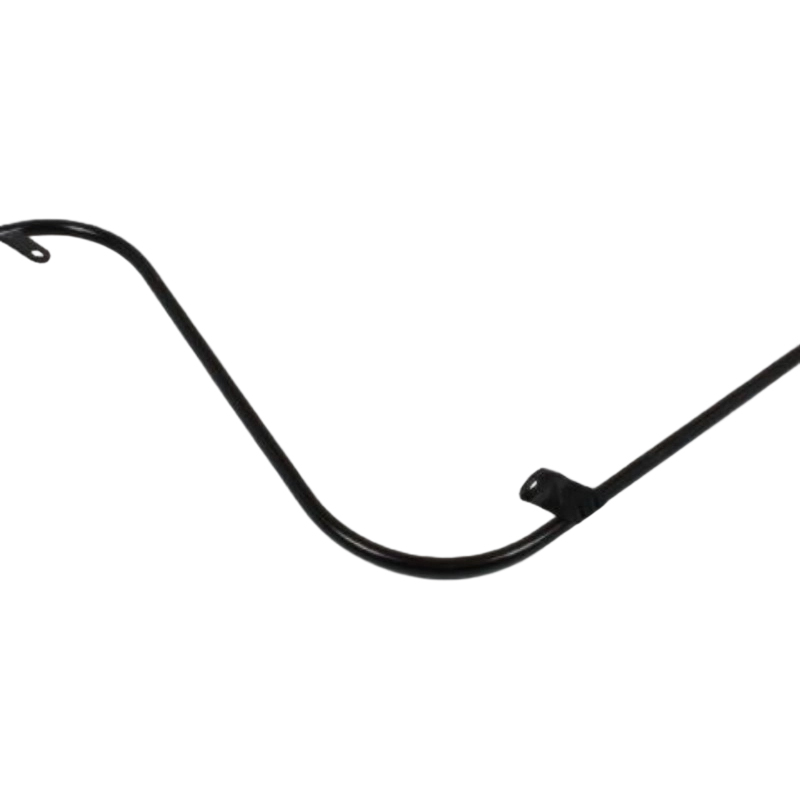

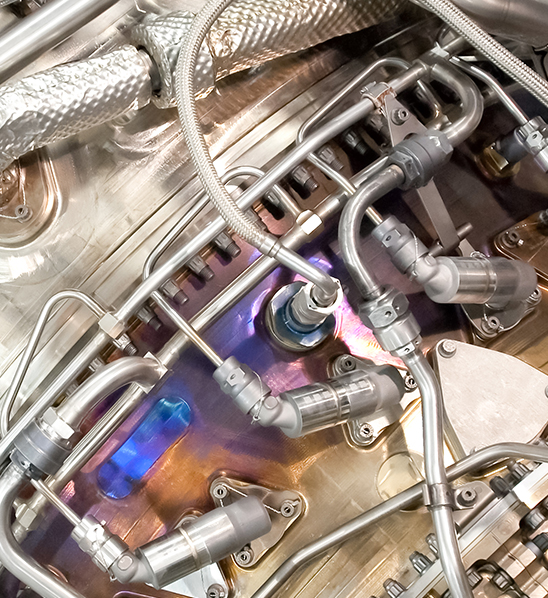

Engine Oil Dipstick Tube

The Engine Oil Dipstick Tube is a cylindrical tube installed in the engine oil pan. It provides access for the oil dipstick (dipstick) and, in some models, also serves as an oil filling or draining function. It is a key component in the engine oil level monitoring system, ensuring maintenance personnel can quickly and accurately check the oil level, observe the oil quality, and add or drain the oil as needed. This component is widely used in various powertrains, including passenger cars, commercial vehicles, engines, generator sets, and construction machinery.

Product Features:

Oil Level Detection Channel

Provides a stable, sealed insertion point for the oil dipstick, allowing maintenance personnel to accurately read the oil level after the engine cools down.

Contamination Prevention

The sealing ring and corrugated end prevent foreign matter and moisture from entering the oil pan, maintaining a clean oil path.

Oil Filling/Draining Aids

Some designs feature a filler port or drain valve at the end of the tube, allowing for direct oil filling or removal, improving maintenance efficiency.

Durability

Made of high-temperature and corrosion-resistant materials, it maintains structural integrity even during extended, high-load operation, reducing replacement frequency.

Easy Replacement: Threaded or snap-on connections make replacement easy and adaptable to a variety of engine configurations.

About JIATIAN

The company is located in Wanhou, Zhanqi Town, Yinzhou District, Ningbo City. It is 25 kilometers away from Ningbo Liushi Airport and 5 kilometers away from Ningbo Coastal Industrial Zone. The surrounding area is beautiful with convenient transportation. The company was established on the basis of the development of Ningbo Xingxin Metal Products Factory (established in 1995), and is a high-tech enterprise specializing in the production of automotive pipe fittings. The company's area is 32,000 square meters; the factory area is 26,000 square meters.

The main products of the company are: manufacturing and development of automotive corrugated pipes. Currently, there are 10 CNC fully automatic pipe bending machines, 2 large-scale brazing furnaces assembly lines, 10 various specifications hydraulic internal forming machines (with the maximum processing length of 1.5 meters and diameters ranging from ¢10 to ¢80), 1 800T hydraulic water expansion machine, 4 fully automatic laser welders, 4 sets of welding robots, 8 large-scale machining centers, 6 Panasonic arc welding machines, and over 30 various supporting pipe forming machines. The company has its own R&D and processing centers. The water expansion corrugated pipe equipment and technology of the company are currently at the industry leading level. A comprehensive laboratory has been established.

The company is committed to creating the world's leading automotive bellows with outstanding quality and innovative technology, ensuring that each product can perform well in various environments and promoting the progress of the industry.

News and Information

-

How Does a Faulty EGR Pipe Affect My Car's Performance?It’s a scenario many drivers have experienced. You’re driving along, and suddenly, your trusted vehicle feels different. Maybe the check engine light flickers on, or you notice a rough idle when you’r...view More

Dec 08, 2025 ? Industry News

-

A clever solution to the truck's exhaust brake problemAbstract: Frequent use of the exhaust brake makes it difficult to damage the headstock. This is a common problem for many truck drivers. I consulted with experienced drivers, and some believe that the...view More

Oct 27, 2025 ? Industry News

-

The exhaust pipe is black, what's going on?Summary: I believe many car enthusiasts have experienced this: Why is the exhaust pipe white? What should I do if it's white? Is it a sign of a car problem? Recently […] I believe many car enthusiasts...view More

Oct 27, 2025 ? Industry News

-

Car modification knowledge: the benefits of changing the exhaust manifoldAbstract: The exhaust manifold is a key component that collects exhaust gases from all engine cylinders and discharges them out of the vehicle. The efficiency of the entire exhaust system depends on i...view More

Oct 27, 2025 ? Industry News

-

Introduction to Automobile Oil Return PipeAbstract: The function of a vehicle's oil return line: It allows excess oil to return to the tank, reducing fuel consumption. Not all vehicles have an oil return line. Return Line Filter […] The funct...view More

Oct 27, 2025 ? Industry News

JIATIAN’s Engine Oil Dipstick Tube is a critical component in engine oil level monitoring systems, and the Engine Oil Dipstick Tube is also a core offering in JIATIAN’s automotive pipe fittings product line, with the Engine Oil Dipstick Tube serving as a bridge between maintenance personnel and engine lubrication system status. As a high-tech enterprise rooted in Ningbo’s automotive parts manufacturing industry (evolved from Ningbo Xingxin Metal Products Factory established in 1995), JIATIAN has built a 32,000-square-meter production base (26,000-square-meter factory area) in Wanhou, Zhanqi Town, Yinzhou District—conveniently located 25km from Ningbo Liushi Airport and 5km from Ningbo Coastal Industrial Zone. Leveraging its advanced pipe forming equipment (including 10 CNC automatic pipe bending machines, 4 fully automatic laser welders, and an 800T hydraulic water expansion machine), JIATIAN’s Engine Oil Dipstick Tube products deliver stable performance across powertrain scenarios, from passenger cars to construction machinery.

1. Working Principle of Engine Oil Dipstick Tube

Installation & Sealing: The cylindrical tube is mounted to the engine oil pan via threaded or snap-on connections (a process optimized by JIATIAN’s hydraulic internal forming machines, which handle pipes of φ10–φ80 diameter and up to 1.5m length). Its integrated sealing ring and corrugated end (fabricated with JIATIAN’s industry-advanced water expansion corrugated pipe technology) form a closed channel that isolates the oil pan from external contaminants.

Level Detection: The oil dipstick inserts into the tube to reach the oil pan’s oil pool. After the engine cools, the dipstick’s oil adhesion level reflects the actual oil volume in the pan, while the tube’s smooth inner wall ensures the dipstick moves freely for accurate readings.

Auxiliary Fluid Management: For models with filler/drain functions, the tube’s end port acts as a dedicated channel for oil addition or removal, eliminating the need for disassembly of other engine components.

2. Product Specification & Performance Comparison

The following table compares JIATIAN’s Engine Oil Dipstick Tube series with conventional products, and differentiates between JIATIAN’s three core models based on application scenarios:

|

Comparison Dimension |

Conventional Oil Dipstick Tube | JIATIAN Model A (Passenger Car) | JIATIAN Model B (Commercial Vehicle) | JIATIAN Model C (Construction Machinery) |

|---|---|---|---|---|

| Material | Ordinary steel (low corrosion resistance) | High-temperature alloy steel (JIATIAN brazing furnace processed) | Thickened corrosion-resistant steel | Heat-resistant alloy (laser-welded via JIATIAN’s automated equipment) |

| Connection Type | Single threaded (prone to loosening) | Snap-on + sealing ring | Reinforced threaded (CNC-machined) | Heavy-duty snap-lock (machining center finished) |

| Additional Function | Only dipstick access | Basic oil filling port | Oil filling + drain valve | High-pressure resistant oil drain port |

| Operating Temperature Range | -20°C to 120°C | -30°C to 150°C | -40°C to 160°C | -50°C to 180°C |

| Service Life (Lab Test) | ≤ 30,000 hours | ≥ 50,000 hours | ≥ 60,000 hours | ≥ 70,000 hours |

| Core Craft Advantage | None | Water expansion corrugated end | Robotic welding joint | Hydraulic internal forming for pressure resistance |

3. Application Cases of JIATIAN Engine Oil Dipstick Tube

Passenger Car Scenario: Adopted by domestic compact sedan manufacturers, JIATIAN Model A tubes have been installed in over 200,000 vehicles since 2021. The snap-on connection reduces assembly time by 15% for OEMs, while the corrosion-resistant alloy material has zero reported leakage issues over 3 years of operation.

Commercial Vehicle Scenario: A leading heavy-duty truck brand uses JIATIAN Model B tubes for its long-haul fleet. The integrated drain valve cuts oil change time by 20% for maintenance teams, and the reinforced threads withstand the vibration of 10-ton payloads without loosening.

Construction Machinery Scenario: JIATIAN Model C tubes are fitted to excavators operating in high-temperature mining environments. The heat-resistant alloy and laser-welded joints maintain structural integrity even under continuous 12-hour high-load operation, with a replacement rate 40% lower than conventional products.

All cases leverage JIATIAN’s comprehensive laboratory testing (including pressure and temperature cycling) to ensure compatibility with harsh working conditions.

4. Maintenance Guidance for Engine Oil Dipstick Tube

Proper maintenance extends the service life of the Engine Oil Dipstick Tube, and JIATIAN recommends the following steps :

Regular Sealing Inspection (Every 10,000km): Check the tube’s sealing ring for cracks or deformation. JIATIAN’s corrugated end seals are designed for 50,000km of service, but extreme environments may require earlier replacement .

Contamination Removal (Every 20,000km): Clean the tube’s inner wall with specialized engine cleaning fluid to prevent sludge buildup (JIATIAN’s smooth inner wall, formed by hydraulic internal machines, reduces sludge adhesion by 30% compared to standard tubes).

Connection Tightness Check (Before each heavy-load operation): For threaded models, ensure torque meets JIATIAN’s factory specifications (15–20 N·m for passenger cars, 25–30 N·m for commercial vehicles) to avoid oil leakage.

Replacement Criterion: Replace the tube if it shows corrosion pitting (depth > 0.5mm) or structural deformation—JIATIAN’s threaded/snap-on designs enable replacement in under 30 minutes without professional tools.

5. FAQ About JIATIAN Engine Oil Dipstick Tube

Q1: Can JIATIAN’s Engine Oil Dipstick Tube be customized for non-standard engine models?

A: Yes. JIATIAN’s R&D and processing centers (equipped with 8 large machining centers and 10 hydraulic internal forming machines) support custom tube lengths (up to 1.5m) and diameters (φ10–φ80).?

Q2: How does JIATIAN ensure the high-temperature resistance of its tubes?

A: JIATIAN uses high-temperature alloy materials and processes them via 2 large-scale brazing furnace assembly lines, which create uniform material density.?

Q3: What is the delivery lead time for JIATIAN’s Engine Oil Dipstick Tube?

A: For standard models, lead time is 7–10 working days (supported by JIATIAN’s 26,000-square-meter factory and automated production lines).?

JIATIAN’s Engine Oil Dipstick Tube series embodies the company’s commitment to innovative technology and outstanding quality, with each product manufactured to promote the reliability of automotive lubrication systems and drive industry progress in automotive pipe fittings.

English

English Espa?ol

Espa?ol