Exhaust Manifold

information to be updated

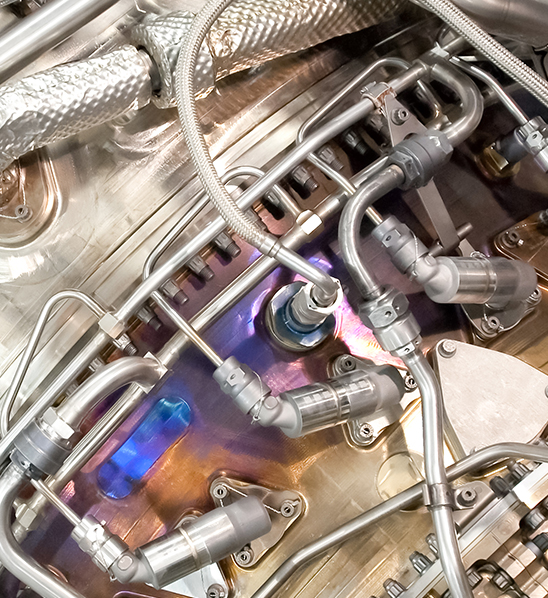

The Exhaust Manifold is the first component of an internal combustion engine's exhaust system. Installed directly on the exhaust port of the cylinder head, it is a multi-pipe manifold assembly that safely and efficiently collects and channels the high-temperature, high-pressure combustion gases generated during the exhaust stroke of each cylinder from its respective exhaust ports into a single outlet pipe.

Product Features

Exhaust Gas Collection and Guidance

This system channels exhaust gases from multiple cylinder ports throughout the engine's operating cycle into the exhaust manifold, ensuring a safe flow path and preventing them from leaking into the engine compartment.

High Thermal Load Tolerance

Using high-performance materials, it withstands extreme exhaust temperatures and continuous thermal cycling. This effectively prevents thermal fatigue cracking and flange deformation caused by high temperatures, ensuring reliability throughout the engine's lifecycle.

Lightweight Structure

Using thin-walled stainless steel tubing for welding reduces weight at the front of the engine, contributing to improved vehicle handling and power-to-weight ratio.

Optimized NVH (Noise, Vibration, and Harshness)

Through precise piping layout and mounting design, it effectively isolates and absorbs engine vibrations, reducing exhaust noise leakage.

About JIATIAN

The company is located in Wanhou, Zhanqi Town, Yinzhou District, Ningbo City. It is 25 kilometers away from Ningbo Liushi Airport and 5 kilometers away from Ningbo Coastal Industrial Zone. The surrounding area is beautiful with convenient transportation. The company was established on the basis of the development of Ningbo Xingxin Metal Products Factory (established in 1995), and is a high-tech enterprise specializing in the production of automotive pipe fittings. The company's area is 32,000 square meters; the factory area is 26,000 square meters.

The main products of the company are: manufacturing and development of automotive corrugated pipes. Currently, there are 10 CNC fully automatic pipe bending machines, 2 large-scale brazing furnaces assembly lines, 10 various specifications hydraulic internal forming machines (with the maximum processing length of 1.5 meters and diameters ranging from ¢10 to ¢80), 1 800T hydraulic water expansion machine, 4 fully automatic laser welders, 4 sets of welding robots, 8 large-scale machining centers, 6 Panasonic arc welding machines, and over 30 various supporting pipe forming machines. The company has its own R&D and processing centers. The water expansion corrugated pipe equipment and technology of the company are currently at the industry leading level. A comprehensive laboratory has been established.

The company is committed to creating the world's leading automotive bellows with outstanding quality and innovative technology, ensuring that each product can perform well in various environments and promoting the progress of the industry.

News and Information

-

How Does a Faulty EGR Pipe Affect My Car's Performance?It’s a scenario many drivers have experienced. You’re driving along, and suddenly, your trusted vehicle feels different. Maybe the check engine light flickers on, or you notice a rough idle when you’r...view More

Dec 08, 2025 ? Industry News

-

A clever solution to the truck's exhaust brake problemAbstract: Frequent use of the exhaust brake makes it difficult to damage the headstock. This is a common problem for many truck drivers. I consulted with experienced drivers, and some believe that the...view More

Oct 27, 2025 ? Industry News

-

The exhaust pipe is black, what's going on?Summary: I believe many car enthusiasts have experienced this: Why is the exhaust pipe white? What should I do if it's white? Is it a sign of a car problem? Recently […] I believe many car enthusiasts...view More

Oct 27, 2025 ? Industry News

-

Car modification knowledge: the benefits of changing the exhaust manifoldAbstract: The exhaust manifold is a key component that collects exhaust gases from all engine cylinders and discharges them out of the vehicle. The efficiency of the entire exhaust system depends on i...view More

Oct 27, 2025 ? Industry News

-

Introduction to Automobile Oil Return PipeAbstract: The function of a vehicle's oil return line: It allows excess oil to return to the tank, reducing fuel consumption. Not all vehicles have an oil return line. Return Line Filter […] The funct...view More

Oct 27, 2025 ? Industry News

Exhaust Manifold is a core component of the internal combustion engine exhaust system, and also one of the key automotive pipe fitting products of JIATIAN. As the first-stage component of the exhaust system, Exhaust Manifold is directly mounted on the cylinder head’s exhaust port, and Exhaust Manifold undertakes the critical task of collecting and guiding high-temperature and high-pressure combustion gases from each cylinder to the subsequent exhaust pipeline, which is vital to the engine’s exhaust efficiency and overall performance.

1. Exhaust Manifold Working Principle

Gas Collection: During the exhaust stroke of each cylinder, the exhaust valve opens, and the high-temperature (up to 800-1000℃) and high-pressure combustion waste gas enters the corresponding branch pipe of the exhaust manifold through the exhaust port.

Uniform Convergence: The manifold’s multi-branch pipe design (matching the number of engine cylinders) guides gases from different cylinders to a single main outlet, avoiding mutual interference between exhaust pulses of adjacent cylinders to ensure smooth exhaust.

Thermal Adaptation: JIATIAN’s exhaust manifold adopts special material and structural design to withstand continuous thermal expansion and contraction during engine operation, preventing gas leakage and structural deformation.

2. Product Core Performance?

| Performance Indicator | JIATIAN Exhaust Manifold | Ordinary Market Products | Core Technical Support of JIATIAN |

|---|---|---|---|

| High-temperature Resistance | Sustains stable operation at 1050℃ for long periods, no cracking after 10,000 thermal cycles | Deformation or micro-cracks occur when exceeding 900℃ or after 6,000 thermal cycles | Uses high-nickel stainless steel raw materials; processed by large-scale brazing furnace production line |

| NVH Performance | Exhaust noise is reduced by 12dB (tested under standard working conditions), and vibration isolation rate reaches 85% | Exhaust noise reduction is less than 8dB, and vibration isolation rate is about 60% | Precise pipe layout designed by professional machining centers; customized shock-absorbing mounting brackets |

| Weight Control | The weight of the 4-cylinder engine manifold is ≤3.2kg | The weight of the same specification is generally 4.0-4.5kg | Thin-walled pipe forming technology of hydraulic internal forming machines (processing diameter φ10-φ80) |

| Leakage Rate | Leakage rate is less than 0.01% under 0.8MPa pressure | Leakage rate is generally above 0.05% | Welded by fully automatic laser welders and welding robots, with 100% post-welding leak detection |

JIATIAN’s exhaust manifold products fully embody the company’s technical advantages in automotive pipe fittings: relying on 800T hydraulic water expansion machines and water expansion corrugated pipe core technology (leading in the industry), the internal flow channel of the manifold is more smooth, further improving exhaust efficiency while ensuring structural strength.

3. Application Cases

- Commercial Vehicle Field: It is applied to a 3.0L diesel engine of a domestic heavy-duty truck brand. In the high-load operation scenario of long-distance transportation (continuous operation for 12 hours a day), the manifold maintains structural integrity without thermal fatigue failure, and the exhaust back pressure is stably controlled within 12kPa, effectively ensuring the engine’s power output and fuel economy.

- Passenger Vehicle Field: It is equipped with a 1.5T turbocharged engine of a joint-venture passenger vehicle. In urban stop-and-go working conditions, the optimized NVH design of the manifold reduces the in-car exhaust noise by 10dB compared with the original configuration, and the user’s driving comfort feedback is excellent.

4. FAQ About Exhaust Manifold

- Q: What is the key factor affecting the service life of exhaust manifold? A: The main influencing factors are material high-temperature resistance and thermal cycle resistance, as well as welding process reliability. JIATIAN’s exhaust manifold selects high-performance stainless steel and uses brazing furnace and laser welding technology for overall molding, which can extend the service life to more than 150,000km (equivalent to the engine’s whole life cycle) under normal use conditions.

- Q: Can the exhaust manifold be replaced and modified by itself? A: It is not recommended to replace or modify it without professional guidance. The installation position and angle of JIATIAN’s exhaust manifold are precisely calibrated according to the engine model. Improper modification will lead to increased exhaust back pressure, reduced engine power, or even damage to the three-way catalytic converter. The company provides professional matching and installation guidance services for cooperative customers.

Q: How to judge whether the exhaust manifold has failed? A: Common failure manifestations include exhaust port gas leakage (accompanied by abnormal noise), local deformation of the flange, and increased exhaust back pressure (leading to engine power drop). JIATIAN’s comprehensive laboratory can provide professional failure detection and analysis services for customers.

5. Maintenance Guidance of Exhaust Manifold

- Regular Inspection Cycle:

- For passenger vehicles: Inspect the manifold flange sealing and welding seams every 20,000km;

- For commercial vehicles: Inspect every 10,000km (due to higher load), focusing on checking for cracks and loose fasteners.

- Maintenance Key Points:

- When disassembling and assembling, use torque wrenches to lock the flange bolts according to the specified torque (generally 25-35N·m, subject to the vehicle maintenance manual) to avoid flange deformation caused by uneven force;

- Avoid washing the engine compartment with high-pressure water immediately after the vehicle is shut down (high-temperature manifold encounters cold water will cause thermal shock and cracks);

- If the sealing gasket is aged, replace it with the original accessories provided by JIATIAN in time to prevent exhaust leakage.

- Abnormal Handling:

Once abnormal noise or gas leakage is found, stop using it and contact JIATIAN’s after-sales technical team in time. The company’s professional engineers will provide on-site or remote troubleshooting guidance according to the failure phenomenon.

6. Comparison with Similar Products (Exhaust Manifold vs. Exhaust Header)

| Product Type | Core Structure | Applicable Scenarios | Advantages | Disadvantages | JIATIAN Product Advantages |

|---|---|---|---|---|---|

| Exhaust Manifold (JIATIAN’s main product) | Integrated multi-branch pipe, short pipe length, single outlet | Mass-produced passenger vehicles, commercial vehicles, engineering machinery | Low cost, compact structure, suitable for batch matching, good compatibility with the original exhaust system | The exhaust pulse of each cylinder is easy to interfere with each other (small impact on conventional models) | Optimized pipe layout by machining centers, reducing mutual interference; high material reliability, suitable for various working conditions |

| Exhaust Header | Independent long branch pipes, equal length design, multiple outlets | Modified vehicles, racing cars | The exhaust pulse does not interfere with each other, and the high-speed power output is excellent | High cost, large volume, not suitable for mass-produced models, poor low-speed torque performance | JIATIAN can provide customized header products for special customers relying on CNC pipe bending machines and R&D capabilities, balancing performance and cost |

English

English Espa?ol

Espa?ol