Fuel Injector Feed Pipe

Fuel Injector Feed Pipe

Fuel Injector Feed Pipe

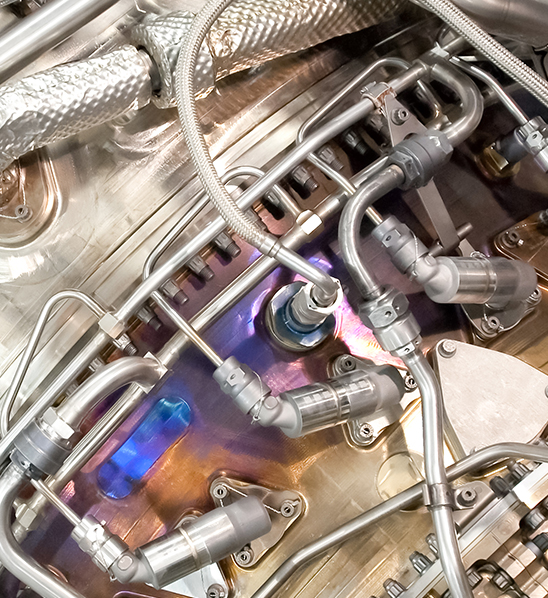

The Fuel Injector Feed Pipe is a precision-engineered metal pipe used to precisely deliver ultra-high-pressure fuel, stored and stabilized in the common rail, to the injectors in each cylinder.

Product Advantages:

Cold Work Hardening and Heat Treatment: Multiple precision cold drawing processes enhance the pipe's grain density and strength. Subsequent heat treatment ensures uniform internal structure and eliminates stress.

Autoclaving Prestressing: Utilizing an industry-leading autoclaving process, water pressure far exceeding the operating pressure creates permanent residual compressive stress in the pipe's inner wall. This stress significantly resists tensile fatigue caused by high-pressure fuel, extending fatigue life several times.

Special Alloy Steel: We select alloy steel pipes with exceptionally high tensile strength and fatigue resistance, specifically tailored to the corrosive and pressure-pulsating characteristics of high-pressure fuel.

Strict Cleanliness Management: After all machining operations, our high-pressure pipes undergo multi-stage ultrasonic cleaning and high-pressure solvent flushing to thoroughly remove metal particles, oil, and impurities. All finished products undergo internal cleanliness testing (meeting stringent standards such as ISO 4406) using a professional particle counter before leaving the factory, and are capped and packaged in a dust-free environment.

About JIATIAN

The company is located in Wanhou, Zhanqi Town, Yinzhou District, Ningbo City. It is 25 kilometers away from Ningbo Liushi Airport and 5 kilometers away from Ningbo Coastal Industrial Zone. The surrounding area is beautiful with convenient transportation. The company was established on the basis of the development of Ningbo Xingxin Metal Products Factory (established in 1995), and is a high-tech enterprise specializing in the production of automotive pipe fittings. The company's area is 32,000 square meters; the factory area is 26,000 square meters.

The main products of the company are: manufacturing and development of automotive corrugated pipes. Currently, there are 10 CNC fully automatic pipe bending machines, 2 large-scale brazing furnaces assembly lines, 10 various specifications hydraulic internal forming machines (with the maximum processing length of 1.5 meters and diameters ranging from ¢10 to ¢80), 1 800T hydraulic water expansion machine, 4 fully automatic laser welders, 4 sets of welding robots, 8 large-scale machining centers, 6 Panasonic arc welding machines, and over 30 various supporting pipe forming machines. The company has its own R&D and processing centers. The water expansion corrugated pipe equipment and technology of the company are currently at the industry leading level. A comprehensive laboratory has been established.

The company is committed to creating the world's leading automotive bellows with outstanding quality and innovative technology, ensuring that each product can perform well in various environments and promoting the progress of the industry.

News and Information

-

How Does a Faulty EGR Pipe Affect My Car's Performance?It’s a scenario many drivers have experienced. You’re driving along, and suddenly, your trusted vehicle feels different. Maybe the check engine light flickers on, or you notice a rough idle when you’r...view More

Dec 08, 2025 ? Industry News

-

A clever solution to the truck's exhaust brake problemAbstract: Frequent use of the exhaust brake makes it difficult to damage the headstock. This is a common problem for many truck drivers. I consulted with experienced drivers, and some believe that the...view More

Oct 27, 2025 ? Industry News

-

The exhaust pipe is black, what's going on?Summary: I believe many car enthusiasts have experienced this: Why is the exhaust pipe white? What should I do if it's white? Is it a sign of a car problem? Recently […] I believe many car enthusiasts...view More

Oct 27, 2025 ? Industry News

-

Car modification knowledge: the benefits of changing the exhaust manifoldAbstract: The exhaust manifold is a key component that collects exhaust gases from all engine cylinders and discharges them out of the vehicle. The efficiency of the entire exhaust system depends on i...view More

Oct 27, 2025 ? Industry News

-

Introduction to Automobile Oil Return PipeAbstract: The function of a vehicle's oil return line: It allows excess oil to return to the tank, reducing fuel consumption. Not all vehicles have an oil return line. Return Line Filter […] The funct...view More

Oct 27, 2025 ? Industry News

Fuel Injector Feed Pipe: Critical Component for High-Pressure Fuel Systems

In modern automotive engines, precision fuel delivery is crucial to maximize efficiency and minimize emissions. The Fuel Injector Feed Pipe is a critical component that ensures high-pressure fuel from the common rail reaches the injectors in each cylinder with absolute accuracy.

Basic Understanding: What is a Fuel Injector Feed Pipe?

A Fuel Injector Feed Pipe is a high-precision metal pipe designed to transport ultra-high-pressure fuel to the injectors in a vehicle’s engine. This pipe plays a vital role in maintaining consistent pressure and preventing fuel flow interruptions, which is essential for engine performance and efficiency.

Core Technologies:

The Fuel Injector Feed Pipe stands out due to its sophisticated manufacturing process, which involves several key technologies to enhance performance and durability:

Cold Work Hardening and Heat Treatment: This process involves multiple cold-drawing stages that improve the pipe's grain density, making it stronger and more durable. Heat treatment ensures an even internal structure, removing stress and enhancing material stability.

Autoclaving Prestressing: By utilizing a unique autoclaving process, the pipe is subjected to water pressure far exceeding its operational capacity. This process induces permanent compressive stress inside the pipe, which improves fatigue resistance and significantly extends its operational life, even under extreme pressure conditions.

Special Alloy Steel: The use of specially selected alloy steel enhances the pipe's tensile strength and resistance to fatigue, ensuring longevity in the high-pressure, pulsating environment of fuel systems.

Strict Cleanliness Management: Ensuring the cleanliness of the pipe is crucial to avoid contamination that could affect engine performance. After manufacturing, the pipe undergoes ultrasonic cleaning and high-pressure solvent flushing. It is tested for cleanliness against strict industry standards (such as ISO 4406) before it is capped, packaged, and sent out for use.

Industry Trends:?

As the automotive industry moves toward more efficient and environmentally friendly solutions, the demand for advanced high-pressure fuel systems is increasing. Innovations like the Fuel Injector Feed Pipe are helping to meet these demands by providing higher performance, longer life, and more reliable operation under extreme conditions.

Emissions Regulations: Stricter emissions standards are pushing automakers to adopt more efficient fuel systems. A precise fuel injector feed system ensures that fuel is delivered accurately, which helps reduce engine emissions.

Fuel Efficiency: With increasing pressure to improve fuel efficiency, optimizing fuel delivery through components like the injector feed pipe is key to improving overall engine performance.

Advanced Manufacturing: The automotive industry is increasingly relying on advanced manufacturing techniques, such as CNC machining, laser welding, and robotic welding, to ensure the highest levels of precision and quality in components like the Fuel Injector Feed Pipe.

Product Comparison and Application Table

| Feature | Fuel Injector Feed Pipe | Traditional Fuel Pipes |

|---|---|---|

| Material | Special Alloy Steel | Standard Steel |

| Pressure Resistance | Ultra-High Pressure Capability | Moderate Pressure |

| Cleaning Process | Multi-stage Ultrasonic Cleaning | Basic Cleaning |

| Fatigue Life | Significantly Extended | Standard Durability |

| Application | High-Performance Engines | Conventional Engines |

FAQs

-

Why is autoclaving prestressing important?

Autoclaving prestressing increases the pipe’s resistance to fatigue, making it ideal for high-pressure fuel systems that undergo constant pressure fluctuations. -

How does the cleanliness of the fuel injector feed pipe impact engine performance?

Any contamination in the fuel injector feed pipe, such as metal particles or oil residues, can disrupt fuel flow and affect engine efficiency, leading to performance issues and increased emissions. That's why thorough cleaning is essential. -

What makes the special alloy steel different from standard steel?

Special alloy steel has a higher tensile strength and resistance to corrosion and fatigue, making it more suitable for the harsh environment of high-pressure fuel systems. -

What applications are these pipes suitable for?

These pipes are ideal for use in high-performance automotive engines, especially those requiring precise fuel delivery under extreme pressure conditions.

English

English Espa?ol

Espa?ol