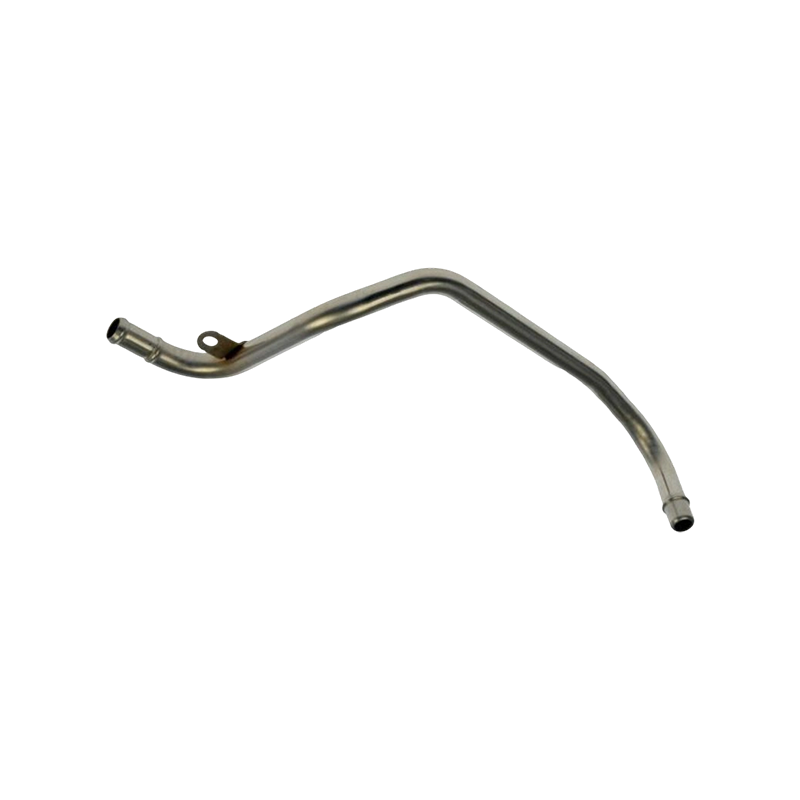

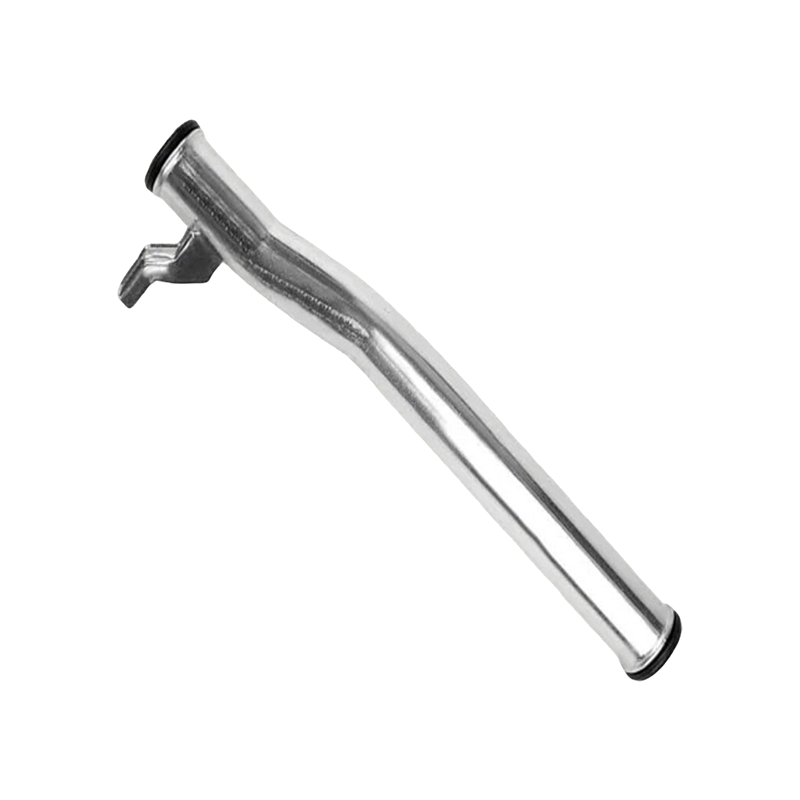

HVAC Heater Hose Assembly

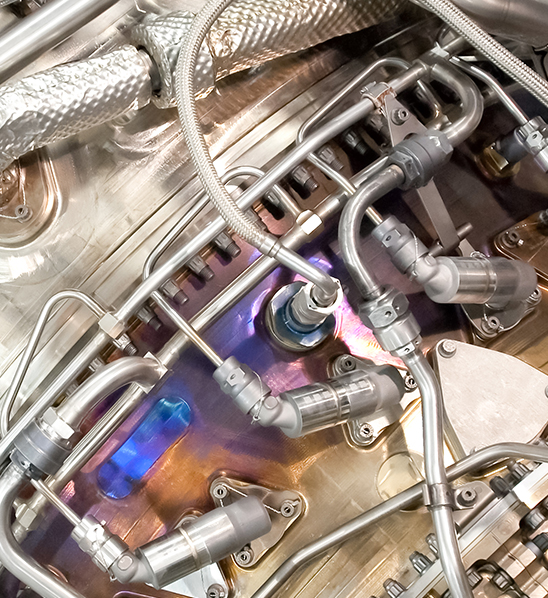

The HVAC Heater Hose Assembly is a crucial component in a vehicle's heating, ventilation, and air conditioning (HVAC) system. It transports high-temperature coolant from the engine's cooling system to the vehicle's heater core. This assembly typically consists of prefabricated rubber hoses, connectors, metal pipe sections (on select models), and necessary seals, ensuring efficient and safe introduction of engine heat into the cabin for interior heating.

Product Features:

Made of high-quality rubber and other durable materials, it withstands the chemical corrosion of high-temperature coolant and coolant additives.

Pre-molded with specific bends and lengths, it includes factory-style quick connectors or fittings, ensuring a direct replacement and easy installation.

The reliable sealing design, including some steel sections with corrosion-resistant coatings, effectively prevents coolant leaks and environmental corrosion.

As a channel for the heat carrier (coolant), its structure and materials help minimize heat loss and ensure efficient operation of the heating system.

About JIATIAN

The company is located in Wanhou, Zhanqi Town, Yinzhou District, Ningbo City. It is 25 kilometers away from Ningbo Liushi Airport and 5 kilometers away from Ningbo Coastal Industrial Zone. The surrounding area is beautiful with convenient transportation. The company was established on the basis of the development of Ningbo Xingxin Metal Products Factory (established in 1995), and is a high-tech enterprise specializing in the production of automotive pipe fittings. The company's area is 32,000 square meters; the factory area is 26,000 square meters.

The main products of the company are: manufacturing and development of automotive corrugated pipes. Currently, there are 10 CNC fully automatic pipe bending machines, 2 large-scale brazing furnaces assembly lines, 10 various specifications hydraulic internal forming machines (with the maximum processing length of 1.5 meters and diameters ranging from ¢10 to ¢80), 1 800T hydraulic water expansion machine, 4 fully automatic laser welders, 4 sets of welding robots, 8 large-scale machining centers, 6 Panasonic arc welding machines, and over 30 various supporting pipe forming machines. The company has its own R&D and processing centers. The water expansion corrugated pipe equipment and technology of the company are currently at the industry leading level. A comprehensive laboratory has been established.

The company is committed to creating the world's leading automotive bellows with outstanding quality and innovative technology, ensuring that each product can perform well in various environments and promoting the progress of the industry.

News and Information

-

How Does a Faulty EGR Pipe Affect My Car's Performance?It’s a scenario many drivers have experienced. You’re driving along, and suddenly, your trusted vehicle feels different. Maybe the check engine light flickers on, or you notice a rough idle when you’r...view More

Dec 08, 2025 ? Industry News

-

A clever solution to the truck's exhaust brake problemAbstract: Frequent use of the exhaust brake makes it difficult to damage the headstock. This is a common problem for many truck drivers. I consulted with experienced drivers, and some believe that the...view More

Oct 27, 2025 ? Industry News

-

The exhaust pipe is black, what's going on?Summary: I believe many car enthusiasts have experienced this: Why is the exhaust pipe white? What should I do if it's white? Is it a sign of a car problem? Recently […] I believe many car enthusiasts...view More

Oct 27, 2025 ? Industry News

-

Car modification knowledge: the benefits of changing the exhaust manifoldAbstract: The exhaust manifold is a key component that collects exhaust gases from all engine cylinders and discharges them out of the vehicle. The efficiency of the entire exhaust system depends on i...view More

Oct 27, 2025 ? Industry News

-

Introduction to Automobile Oil Return PipeAbstract: The function of a vehicle's oil return line: It allows excess oil to return to the tank, reducing fuel consumption. Not all vehicles have an oil return line. Return Line Filter […] The funct...view More

Oct 27, 2025 ? Industry News

I. Core Working Principle of HVAC Heater Hose Assembly

- Workflow When the engine is running, the high-temperature coolant (approximately 80-95℃) flows into the vehicle's heater core through the?inlet pipe, dissipating heat via the core to provide warm air for the cabin. After heat exchange, the low-temperature coolant flows back to the engine cooling system through the?outlet pipe, forming a closed-loop cycle.

- Core Function As a key channel connecting the engine and the heater core, its sealing performance and heat resistance directly determine the heating efficiency of the HVAC system, while also affecting the pressure balance and operational safety of the engine cooling system.

- JIATIAN Product Adaptability JIATIAN's heater hose assembly adopts low thermal conductivity rubber materials and precision pre-molded structures, which can control heat loss during thermal energy transmission to within 5%—far lower than the industry average of 8%-10%—ensuring the efficient operation of the heating system.

II. Performance Parameter Comparison of Mainstream Industry Products

| Performance Indicator | JIATIAN Product | Ordinary Competitors | Industry Standard Requirements |

|---|---|---|---|

| Coolant corrosion resistance (110℃×72h) | Hardness change ≤±5 Shore A, tensile strength change ≤±10% | Hardness change ±10 Shore A, tensile strength change ±20% | Hardness change ≤±10 Shore A, tensile strength change ≤±20% |

| High/low temperature resistance | No cracking at -40℃×24h, no cracking at 125℃×168h | No cracking at -30℃×24h, no cracking at 100℃×168h | No cracking at -40℃×24h, no cracking at 125℃×168h |

| Pressure burst strength (15mm inner diameter) | ≥1.0MPa | ≥0.85MPa | ≥0.85MPa |

| Installation adaptability | OE-style quick connectors, replacement completed in 10 minutes | Ordinary connectors, requiring professional tools, 20-30 minutes for installation | No mandatory requirements |

| Corrosion resistance (salt spray test) | No red rust in 152h, no white rust in 72h | No white rust in 72h, red rust appears in 96h |

No white rust in 72h, no red rust in 152h |

JIATIAN's products outperform ordinary competitors in corrosion resistance, high/low temperature stability, and installation convenience, while fully meeting or even exceeding the requirements of the national?Automotive Heater Hose Technical Specification?(J02.01.34-2003).

III. Key Technical Standards and Material Selection Logic for Heater Hose Assembly

1. Mandatory Industry Technical Specifications

- Dimensional Tolerance: For lengths >1000mm, tolerance ≤±1.4%; for inner diameters 12-19mm, tolerance is +0.3/-0.5mm;

- Material Performance: The Shore hardness of the inner rubber layer is 65±5, and that of the outer rubber layer is 75±5; tensile strength ≥8.0MPa, elongation at break ≥280%;

- Reliability Testing: Must pass rigorous verifications such as vibration resistance (33Hz, 30m/s2, 8h in each of three directions) and salt spray resistance (no red rust in 152h).

2. Scientific Material Selection Logic

- Inner Rubber Layer: JIATIAN uses coolant-resistant nitrile rubber, which can resist chemical erosion from ethylene glycol-based coolants and additives, preventing swelling and aging of the hose inner wall;

- Reinforcement Layer: A built-in polyester fiber braided layer enhances the hose's pressure resistance and prevents bulging and rupture caused by high-pressure coolant;

- Outer Layer/Metal Sections: Anti-aging agents are added to the outer rubber layer, and metal pipes adopt a galvanized layer of over 8μm plus an anti-corrosion coating (JIATIAN's patented process) to resist corrosion from oil and moisture in the engine compartment.

FAQ:

1. What is the service life of a heater hose assembly, and does it need regular replacement?

Under normal working conditions, a high-quality heater hose assembly can last 80,000-150,000 kilometers (about 5-8 years). However, if the vehicle operates in high-temperature, high-humidity, or frequent short-distance driving conditions for a long time, it is recommended to inspect the hose for aging, cracking, and leakage every 60,000 kilometers/4 years. Due to its excellent anti-aging performance, the actual service life of JIATIAN products can be extended by 1-2 years.2. Is insufficient heating of the HVAC system definitely a problem with the heater hose?

Not necessarily. Insufficient heating can be caused by various factors such as heater core blockage, thermostat failure, or insufficient coolant. However, if accompanied by?coolant leakage in the engine compartment or hose bulging, it is highly likely that the heater hose has failed. JIATIAN recommends first checking the hose sealing performance, and its quick-connect design allows for rapid disassembly and inspection of the hose.3. What should be noted after replacing a heater hose?

After replacement, add suitable coolant and bleed air from the hose. Start the engine to normal operating temperature, then check for leakage at the connectors. It is also recommended to run the heating system for 5-10 minutes to verify heating effectiveness. Thanks to the OE-level connector adaptability of JIATIAN products, the risk of leakage after replacement is significantly reduced.4. Why do some vehicle models' heater hoses include metal pipe sections?

Metal pipe sections are mainly used in narrow, high-vibration areas of the engine compartment to improve pipe rigidity and vibration resistance. JIATIAN's metal pipes adopt double protection of anti-corrosion coating and galvanization, ensuring structural stability while preventing leakage caused by metal rust.

English

English Espa?ol

Espa?ol