Products

Products

Products

About JIATIAN

The company is located in Wanhou, Zhanqi Town, Yinzhou District, Ningbo City. It is 25 kilometers away from Ningbo Liushi Airport and 5 kilometers away from Ningbo Coastal Industrial Zone. The surrounding area is beautiful with convenient transportation. The company was established on the basis of the development of Ningbo Xingxin Metal Products Factory (established in 1995), and is a high-tech enterprise specializing in the production of automotive pipe fittings. The company's area is 32,000 square meters; the factory area is 26,000 square meters.

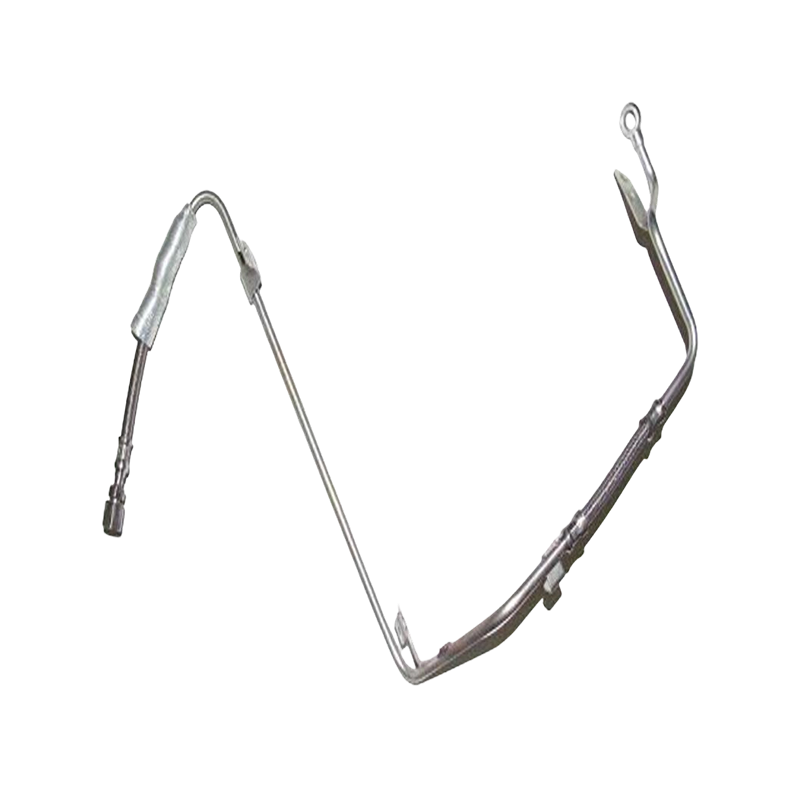

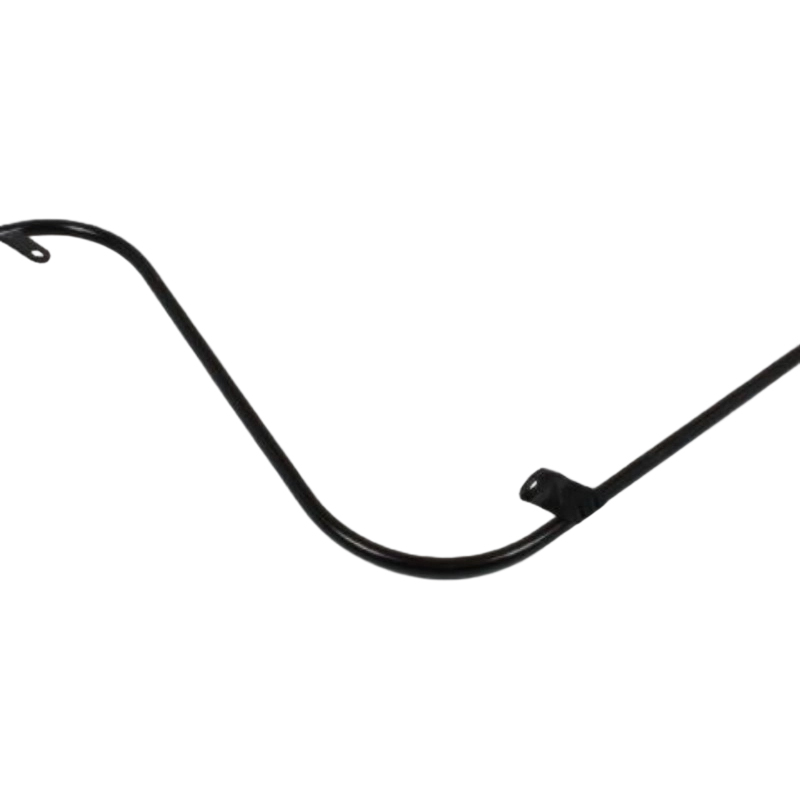

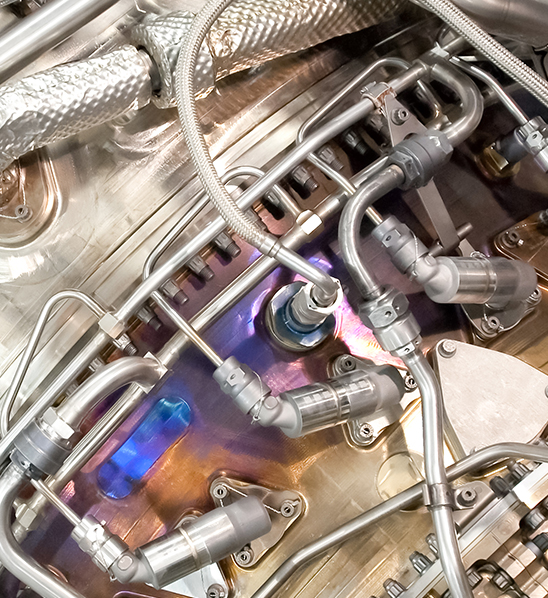

The main products of the company are: manufacturing and development of automotive corrugated pipes. Currently, there are 10 CNC fully automatic pipe bending machines, 2 large-scale brazing furnaces assembly lines, 10 various specifications hydraulic internal forming machines (with the maximum processing length of 1.5 meters and diameters ranging from ¢10 to ¢80), 1 800T hydraulic water expansion machine, 4 fully automatic laser welders, 4 sets of welding robots, 8 large-scale machining centers, 6 Panasonic arc welding machines, and over 30 various supporting pipe forming machines. The company has its own R&D and processing centers. The water expansion corrugated pipe equipment and technology of the company are currently at the industry leading level. A comprehensive laboratory has been established.

The company is committed to creating the world's leading automotive bellows with outstanding quality and innovative technology, ensuring that each product can perform well in various environments and promoting the progress of the industry.

News and Information

-

How Does a Faulty EGR Pipe Affect My Car's Performance?It’s a scenario many drivers have experienced. You’re driving along, and suddenly, your trusted vehicle feels different. Maybe the check engine light flickers on, or you notice a rough idle when you’r...view More

Dec 08, 2025 ? Industry News

-

A clever solution to the truck's exhaust brake problemAbstract: Frequent use of the exhaust brake makes it difficult to damage the headstock. This is a common problem for many truck drivers. I consulted with experienced drivers, and some believe that the...view More

Oct 27, 2025 ? Industry News

-

The exhaust pipe is black, what's going on?Summary: I believe many car enthusiasts have experienced this: Why is the exhaust pipe white? What should I do if it's white? Is it a sign of a car problem? Recently […] I believe many car enthusiasts...view More

Oct 27, 2025 ? Industry News

-

Car modification knowledge: the benefits of changing the exhaust manifoldAbstract: The exhaust manifold is a key component that collects exhaust gases from all engine cylinders and discharges them out of the vehicle. The efficiency of the entire exhaust system depends on i...view More

Oct 27, 2025 ? Industry News

-

Introduction to Automobile Oil Return PipeAbstract: The function of a vehicle's oil return line: It allows excess oil to return to the tank, reducing fuel consumption. Not all vehicles have an oil return line. Return Line Filter […] The funct...view More

Oct 27, 2025 ? Industry News

In the field of automotive engineering,?automotive corrugated pipes?are flexible pipes or sleeves responsible for fluid transfer, motion compensation, and component protection. Their performance directly affects the reliability of critical assemblies such as the fuel system, brake system, cooling system, and suspension system.

The core technical challenges currently faced by the industry include:?-40°C to 150°C?temperature cycling environments; chemical compatibility requirements from contact with media such as?fuel, engine oil, coolant, and brake fluid;?high-frequency vibration?transmitted from the engine and road surface; and weight restrictions imposed by overall vehicle?lightweight design. These operating conditions require a balance of flexibility, sealing, and aging resistance in corrugated pipe materials.

JIATIAN, as a high-tech enterprise specializing in the production of automotive pipe fittings, focuses its technical solutions on?polymer material modification, multi-layer composite structure design, and precision molding processes?to ensure products maintain specified physical and chemical performance throughout their designated lifecycle. The company is located in Wanhou, Zhanqi Town, Yinzhou District, Ningbo City, covering an area of 32,000 square meters with independent R&D and processing centers.

Basic Understanding: Core Concepts and Classification

Automotive corrugated pipes refer to flexible pipes with a regular corrugated wall structure. The corrugated geometry gives them the ability for axial expansion/contraction, radial bending, and vibration absorption, distinguishing them from rigid pipelines.

They can be mainly classified as follows based on function, material, and structure:

1. Classification by Core Function

| Type | Core Function | Typical Application Scenarios |

|---|---|---|

| Fluid Transfer Pipe | Transfers liquids or gases in dynamic connections while maintaining sealing. | Fuel pipes, turbocharger intake pipes, engine coolant pipes. Pipes manufactured by?JIATIAN?are widely used in domestic and international vehicle platforms. |

| Motion Protection Sleeve | Protects rod and shaft-type components, isolating them from dust, sediment, and water. | Shock absorber dust covers, steering tie rod boots, drive shaft boots. |

2. Classification by Main Material

| Material Type | Main Characteristics | Typical Application Scenarios |

|---|---|---|

| Nylon (PA) | Relatively low specific gravity, good wear and chemical resistance. | Automotive wiring harness protective sleeves, coolant pipes. |

| Rubber/Thermoplastic Elastomer (TPE/TPV) | Good elasticity and damping performance. | Various dust covers, sealing boots. |

| Metal (Stainless Steel, etc.) | High temperature and pressure resistance. | Exhaust system flexible joints, heater pipes.?JIATIAN's metal corrugated pipe production line has corresponding processing capabilities. |

| Polypropylene (PP) and other plastics | Lower cost, performance can be improved through modification. | Ventilation pipes, drain pipes, and other low-pressure environments. |

3. Classification by Corrugation Structure

| Structure Type | Structural Characteristics | Main Compensation Direction |

|---|---|---|

| Cross Corrugation | Corrugations form a cross-grid pattern. | Multi-directional bending. |

| Axial Corrugation | Corrugations are arranged parallel to the axis. | Axial expansion/contraction.?JIATIAN's hydraulic internal forming machines can process pipes up to 1.5 meters in length, producing axial corrugated pipes of various specifications. |

Core Technology: Performance Indicators and Implementation

Product performance is defined by quantifiable material and structural indicators and must match specific application conditions.

Key Performance Indicators and Explanation

| Performance Indicator | Technical Definition and Testing Significance | Common Industry Implementation Methods |

|---|---|---|

| Ring Stiffness (SN) | The pipe's ability to resist radial external pressure, measured in kN/m2. A higher value indicates greater resistance to crushing. | Achieved through material reinforcement (e.g., glass fiber), increased wall thickness, or optimized corrugation shape.?JIATIAN?uses 10 CNC fully automatic pipe bending machines and over 30 supporting forming machines to precisely control the forming process and ensure product consistency in ring stiffness. |

| Temperature Resistance Range | The temperature range within which a product can operate long-term without performance degradation exceeding specified limits. | Selection of base materials with good high/low-temperature performance.?JIATIAN?operates 2 large-scale brazing furnace assembly lines for processing high-temperature resistant metal fittings. |

| Media Resistance | The rate of change in parameters such as weight, volume, and strength of a material after immersion in a specific medium (e.g., fuel, coolant). | Selection of compatible materials based on the chemical polarity of the medium. The comprehensive laboratory established by?JIATIAN?can conduct systematic media compatibility testing. |

| Burst Pressure | The internal pressure value at which the pipe ruptures, directly indicating pressure safety. | Utilization of multi-layer composite structures, with inner layers for sealing and reinforcement layers for pressure bearing.?JIATIAN's 800T hydraulic hydroforming machine and hydroforming corrugated pipe technology can create high-strength, high-pressure-resistant corrugated pipe structures. |

| Fatigue Life | The number of cycles of reciprocating motion under specified displacement and frequency until cracks or leaks occur. | Optimization of corrugation peak and valley curves to reduce stress concentration.?JIATIAN's 4 fully automatic laser welders and 4 sets of welding robot workstations ensure uniform and highly consistent welds, improving the fatigue life of welded structural components. |

An example of a material technology: Adding?graphene?to substrates like polyethylene (PE). Laboratory data indicates that this composite material can increase ring stiffness by approximately?20% at room temperature?and by approximately?30% at 45-70°C, while maintaining necessary ring flexibility.

Industry Trends and Evolution of Technical Requirements

The development direction of the automotive industry specifies concrete requirements for component technology.

| Industry Trend | Evolution of Technical Requirements for Corrugated Pipes | JIATIAN's Related Technological Development and Preparedness |

|---|---|---|

| Electrification | Increased demand for battery and motor cooling pipes, with clear requirements for insulation and flame retardancy. | Development of pipeline systems suitable for low-conductivity coolant. The company's R&D center is dedicated to developing new related materials and processes. |

| Lightweighting | Pressure for overall vehicle weight reduction extends to all components, requiring equivalent or higher performance with lower material density. | Increased application proportion of?Nylon (PA) materials. The company's processing capabilities cover pipe forming from ¢10 to ¢80 diameters, meeting the production needs for diverse lightweight pipe fittings. |

| Long Life and High Reliability | Extension of vehicle warranty periods requires improved design life and reliability indicators for components. | Greater emphasis on long-term thermal oxidative aging performance of materials. The company's 8 large machining centers and comprehensive laboratory provide assurance for product reliability design and validation. |

| Globalization and Supply Chain | Products must comply with regulations and standards in different regions and possess stable delivery capabilities. | Located in Ningbo, the company is 25 km from Ningbo Lishe Airport and 5 km from the Ningbo Coastal Industrial Zone. Its geographical location facilitates service to global customers and supply chain integration. |

Frequently Asked Questions

Q: How to select corrugated pipe material for a brake system?

A: Brake systems involve?brake fluid (e.g., DOT3/DOT4). The material must have excellent?brake fluid resistance, with volume change rate and hardness change after long-term immersion within standard limits. It must also meet temperature range requirements above?-40°C to 120°C?and have good?pulse fatigue performance. EPDM or specific nylon materials are typically recommended.?JIATIAN?can provide customers with material selection and product manufacturing that comply with corresponding technical specifications.

Q: What are the special requirements for fuel pipes regarding corrugated pipes?

A: Fuel pipes require three core capabilities:?1. Low fuel permeability?to meet evaporative emission regulations;?2. Resistance to fuel chemical corrosion, including modern ethanol-blended gasoline;?3. Good temperature resistance. Multi-layer structures are common solutions.?JIATIAN's hydroforming corrugated pipe equipment and technology can be used to manufacture fuel pipe fittings with complex internal structures.

Q: How do cooling pipes for electric vehicles differ from those for traditional vehicles?

A: The main differences lie in two aspects:?1. Media and Pressure: EV cooling systems may use?low-conductivity coolant, and system pressure may be higher;?2. Electrical Safety Requirements: Pipe materials require higher?insulation resistance. Materials are typically selected from specific grades of nylon or rubber.?JIATIAN's various specification hydraulic internal forming machines and welding equipment can adapt to the higher precision and reliability requirements for EV cooling pipes.

Q: How to verify the durability and reliability of corrugated pipes?

A: The industry verifies this through a series of bench tests, mainly including:?temperature cycling tests,?media compatibility tests,?vibration fatigue tests,?pulse pressure tests, and?salt spray tests. The comprehensive laboratory established by?JIATIAN?Company has the capability to conduct related tests to verify product durability and reliability.

English

English Espa?ol

Espa?ol