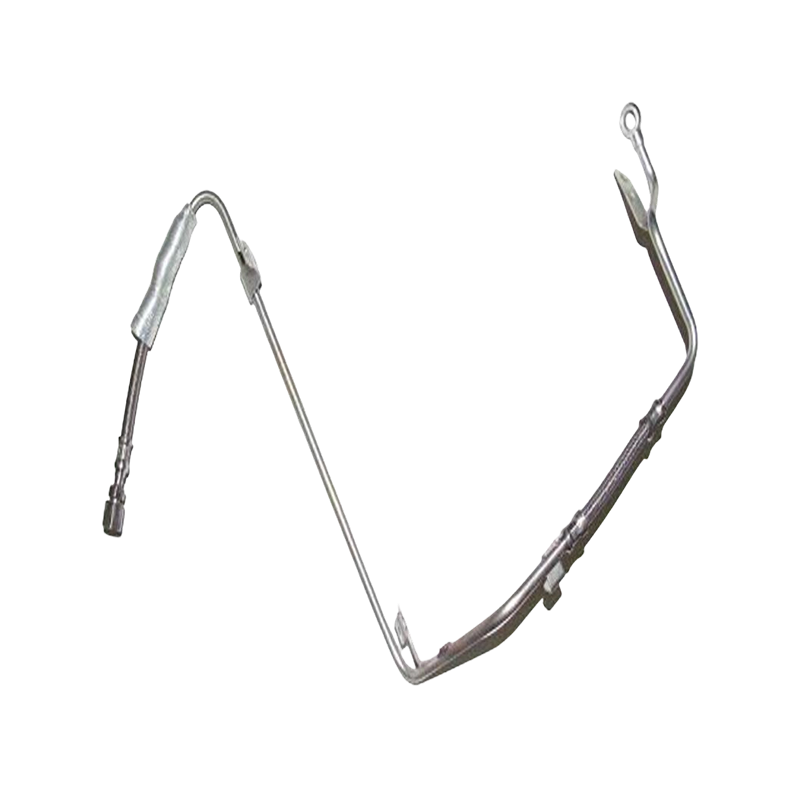

Turbocharger Line

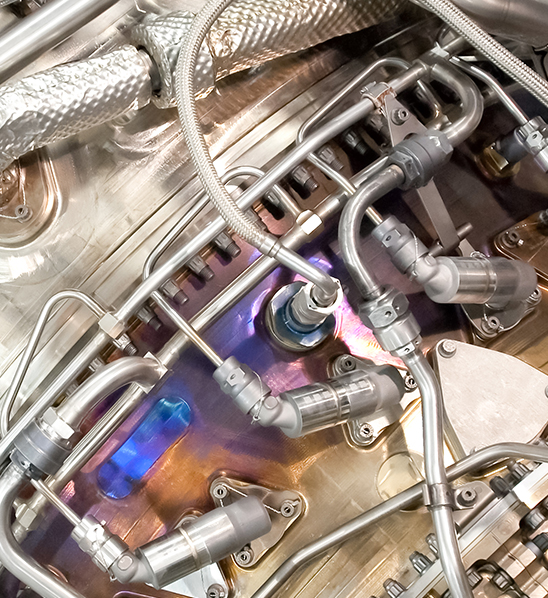

The turbocharger line is the collective term for all critical piping connecting the engine to the turbocharger and its surrounding systems. Its main components include the oil supply line (which delivers pressurized oil for lubrication and cooling), the oil return line (which returns the oil to the oil pan), the intake line (which delivers air to the turbine), and the charge air line (which delivers high-temperature compressed air to the intercooler).

Product Features:

1. High-Temperature Resistance

Using heat-resistant materials such as fluororubber, silicone, stainless steel braided PTFE hose, or specialized metal rigid tubing, these tubings can withstand the extreme temperatures transmitted from the turbocharger center housing and exhaust port (especially the oil line), as well as the high temperatures generated by the compressed air.

2. High-Pressure Resistance

Thick-walled tubing with a multi-layer reinforced structure (for the hose) or high-strength metal (for the rigid tubing) can withstand the high pressures of the engine's oil pressure system (for the oil supply line) and the high-pressure air compressed by the turbine (for the charge air line).

3. Sealing

Using high-quality O-rings, gaskets, and precision-machined fittings, these tubings offer excellent sealing performance, effectively preventing oil, coolant, or charge air leaks.

About JIATIAN

The company is located in Wanhou, Zhanqi Town, Yinzhou District, Ningbo City. It is 25 kilometers away from Ningbo Liushi Airport and 5 kilometers away from Ningbo Coastal Industrial Zone. The surrounding area is beautiful with convenient transportation. The company was established on the basis of the development of Ningbo Xingxin Metal Products Factory (established in 1995), and is a high-tech enterprise specializing in the production of automotive pipe fittings. The company's area is 32,000 square meters; the factory area is 26,000 square meters.

The main products of the company are: manufacturing and development of automotive corrugated pipes. Currently, there are 10 CNC fully automatic pipe bending machines, 2 large-scale brazing furnaces assembly lines, 10 various specifications hydraulic internal forming machines (with the maximum processing length of 1.5 meters and diameters ranging from ¢10 to ¢80), 1 800T hydraulic water expansion machine, 4 fully automatic laser welders, 4 sets of welding robots, 8 large-scale machining centers, 6 Panasonic arc welding machines, and over 30 various supporting pipe forming machines. The company has its own R&D and processing centers. The water expansion corrugated pipe equipment and technology of the company are currently at the industry leading level. A comprehensive laboratory has been established.

The company is committed to creating the world's leading automotive bellows with outstanding quality and innovative technology, ensuring that each product can perform well in various environments and promoting the progress of the industry.

News and Information

-

How Does a Faulty EGR Pipe Affect My Car's Performance?It’s a scenario many drivers have experienced. You’re driving along, and suddenly, your trusted vehicle feels different. Maybe the check engine light flickers on, or you notice a rough idle when you’r...view More

Dec 08, 2025 ? Industry News

-

A clever solution to the truck's exhaust brake problemAbstract: Frequent use of the exhaust brake makes it difficult to damage the headstock. This is a common problem for many truck drivers. I consulted with experienced drivers, and some believe that the...view More

Oct 27, 2025 ? Industry News

-

The exhaust pipe is black, what's going on?Summary: I believe many car enthusiasts have experienced this: Why is the exhaust pipe white? What should I do if it's white? Is it a sign of a car problem? Recently […] I believe many car enthusiasts...view More

Oct 27, 2025 ? Industry News

-

Car modification knowledge: the benefits of changing the exhaust manifoldAbstract: The exhaust manifold is a key component that collects exhaust gases from all engine cylinders and discharges them out of the vehicle. The efficiency of the entire exhaust system depends on i...view More

Oct 27, 2025 ? Industry News

-

Introduction to Automobile Oil Return PipeAbstract: The function of a vehicle's oil return line: It allows excess oil to return to the tank, reducing fuel consumption. Not all vehicles have an oil return line. Return Line Filter […] The funct...view More

Oct 27, 2025 ? Industry News

Turbocharger line is the core piping assembly connecting an engine to its turbocharger and peripheral systems, and it is also a key product category in JIATIAN’s automotive pipe fitting portfolio. Turbocharger line serves as the "vascular system" of the turbocharging unit, with its components (oil supply line, oil return line, intake line, charge air line) undertaking the critical tasks of lubrication, cooling, and air transmission for the turbocharger.

1. Working Principle of Turbocharger Line

Oil supply line: Delivers pressurized engine oil to the turbocharger’s center housing, realizing lubrication of the turbine shaft and bearing, and taking away part of the heat generated during high-speed operation. JIATIAN’s R&D center has optimized the inner diameter and material of the oil supply line based on laboratory test data, ensuring oil flow matches the turbocharger’s operating demand.

Oil return line: Guides the used engine oil back to the oil pan to complete the oil circulation. JIATIAN adopts hydraulic internal forming technology (with maximum processing length of 1.5 meters) to shape the oil return line, ensuring smooth oil flow without blockage.

Intake line: Transmits filtered ambient air to the turbocharger’s compressor impeller for preliminary compression.

Charge air line: Sends high-temperature compressed air from the compressor to the intercooler for cooling, laying the foundation for the engine’s efficient combustion. JIATIAN’s comprehensive laboratory conducts high-temperature and high-pressure durability tests on the charge air line to verify its adaptability to extreme working conditions.

2. Core Performance Comparison of Turbocharger Line

| Performance Index | JIATIAN Turbocharger Line | Ordinary Turbocharger Pipeline | Core Technical Support of JIATIAN |

|---|---|---|---|

| High-temperature resistance | Resists continuous temperature of 200-250℃ (short-term peak 300℃) | Resists continuous temperature of 150-180℃ (short-term peak 200℃) | Adopts fluororubber, stainless steel braided PTFE hose and specialized metal rigid tubing; verified by laboratory high-temperature aging tests |

| High-pressure resistance | Oil supply line withstands 6-8MPa oil pressure; charge air line withstands 2.5-3MPa air pressure | Oil supply line withstands 4-5MPa oil pressure; charge air line withstands 1.5-2MPa air pressure | Thick-walled structure with multi-layer reinforcement (hose); high-strength metal material (rigid tubing); processed by 800T hydraulic water expansion machine |

| Sealing performance | 0 leakage under rated pressure (test duration 72h) | Leakage risk increases after 48h of rated pressure operation | Equipped with precision-machined fittings and high-quality O-rings; assembled with the support of welding robots to ensure connection tightness |

| Service life | ≥ 80,000 km (automotive application scenario) | ≤ 50,000 km (automotive application scenario) | Water expansion corrugated pipe equipment and technology with industry-advanced level; whole-process quality control in 26,000-square-meter factory area |

3. Application Cases of Turbocharger Line

Commercial heavy-duty truck model: A domestic heavy-duty truck manufacturer adopted JIATIAN’s metal rigid turbocharger line for its 6-cylinder diesel engine models. Relying on the high-pressure resistance of the line (withstanding 8MPa oil pressure) and the processing accuracy of CNC fully automatic pipe bending machines, the product solved the problem of oil leakage in the turbocharger lubrication system under long-term high-load operation, and the failure rate of the matching models decreased by 65% compared with the previous configuration.

Passenger car turbocharged gasoline engine model: A joint-venture passenger car brand selected JIATIAN’s silicone + stainless steel braided charge air line for its 1.5T compact SUV models.?

4. Maintenance Guidance for Turbocharger Line

Proper maintenance can effectively extend the service life of turbocharger line.?

Regular inspection cycle:

Daily inspection: Check the surface of the turbocharger line for cracks, deformation, and loose fittings; focus on the connection between the oil line and the turbocharger center housing.

Regular maintenance (every 10,000 km): Conduct pressure testing on the charge air line and oil supply line with professional tools; replace aging O-rings and gaskets in a timely manner .

Key maintenance points:

Avoid violent collision and extrusion of the turbocharger line during engine compartment maintenance to prevent damage to the multi-layer reinforced structure of the hose.

For metal rigid tubing, check the brazing joint ?for oxidation and looseness, and clean the inner wall of the oil return line regularly to prevent oil sludge accumulation.

Professional support: JIATIAN’s comprehensive laboratory can provide third-party testing and maintenance consultation for its turbocharger line users, helping to diagnose potential faults in advance.

5. FAQ about Turbocharger Line

Q1: What factors will affect the service life of turbocharger line?

A1: The service life is mainly affected by working temperature, pressure stability, and assembly accuracy. JIATIAN’s turbocharger line adopts heat-resistant and pressure-resistant materials, and its products are processed by precision equipment such as machining centers, which can effectively reduce the impact of external factors on service life. In addition, irregular maintenance (such as delayed replacement of sealing parts) will also shorten the service life.

Q2: How to select the material of turbocharger line for different engine types?

A2: For diesel engines with high working temperature and load, it is recommended to select metal rigid tubing (JIATIAN’s stainless steel rigid line is suitable); for small-displacement gasoline engines of passenger cars, silicone + stainless steel braided hose is more flexible and space-saving. JIATIAN’s R&D team can provide customized material selection schemes according to the engine’s technical parameters of customers.

Q3: Does JIATIAN provide customized services for turbocharger line?

A3: Yes. JIATIAN has 10 hydraulic internal forming machines and a professional R&D team, which can provide customized processing of turbocharger line with length up to 1.5 meters and diameter ranging from ¢10 to ¢80 according to the customer’s vehicle model and engine layout requirements, and complete the whole process from design to mass production.

JIATIAN is committed to promoting the upgrading of automotive pipe fitting products with innovative technology. Its turbocharger line, relying on advanced production equipment and strict quality control, provides a reliable solution for the stable operation of the automotive turbocharging system, and helps the development of the automotive parts industry.

English

English Espa?ol

Espa?ol