Turbocharger Up Pipe

information to be updated

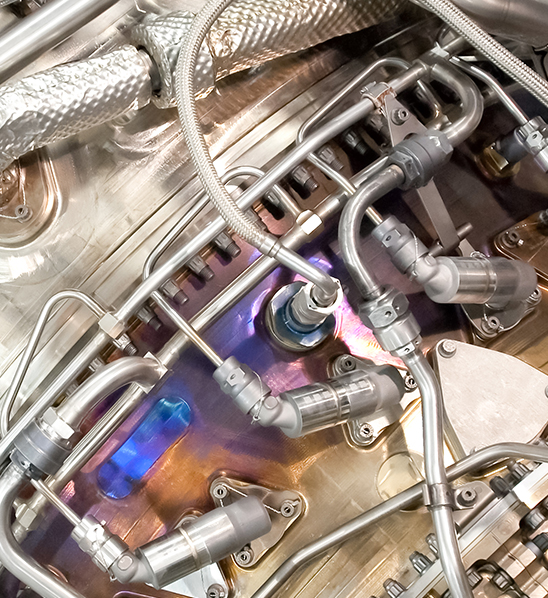

The turbocharger head pipe is a connecting component in the exhaust system of a turbocharged engine. Commonly used in diesel or V-type engine layouts, it directs high-temperature, high-pressure exhaust gases collected by the engine's exhaust manifold to the turbine housing (exhaust side) of the turbocharger located above.

Product Advantages:

Made of high-grade stainless steel, it is resistant to high-temperature oxidation and corrosion, and can withstand prolonged extreme exhaust temperatures.

Designed and manufactured to strict standards of high performance and durability.

In addition to our standard product line, we also provide full-process customized solutions, from single-piece production to mass production, for a wide range of industries and applications.

About JIATIAN

The company is located in Wanhou, Zhanqi Town, Yinzhou District, Ningbo City. It is 25 kilometers away from Ningbo Liushi Airport and 5 kilometers away from Ningbo Coastal Industrial Zone. The surrounding area is beautiful with convenient transportation. The company was established on the basis of the development of Ningbo Xingxin Metal Products Factory (established in 1995), and is a high-tech enterprise specializing in the production of automotive pipe fittings. The company's area is 32,000 square meters; the factory area is 26,000 square meters.

The main products of the company are: manufacturing and development of automotive corrugated pipes. Currently, there are 10 CNC fully automatic pipe bending machines, 2 large-scale brazing furnaces assembly lines, 10 various specifications hydraulic internal forming machines (with the maximum processing length of 1.5 meters and diameters ranging from ¢10 to ¢80), 1 800T hydraulic water expansion machine, 4 fully automatic laser welders, 4 sets of welding robots, 8 large-scale machining centers, 6 Panasonic arc welding machines, and over 30 various supporting pipe forming machines. The company has its own R&D and processing centers. The water expansion corrugated pipe equipment and technology of the company are currently at the industry leading level. A comprehensive laboratory has been established.

The company is committed to creating the world's leading automotive bellows with outstanding quality and innovative technology, ensuring that each product can perform well in various environments and promoting the progress of the industry.

News and Information

-

How Does a Faulty EGR Pipe Affect My Car's Performance?It’s a scenario many drivers have experienced. You’re driving along, and suddenly, your trusted vehicle feels different. Maybe the check engine light flickers on, or you notice a rough idle when you’r...view More

Dec 08, 2025 ? Industry News

-

A clever solution to the truck's exhaust brake problemAbstract: Frequent use of the exhaust brake makes it difficult to damage the headstock. This is a common problem for many truck drivers. I consulted with experienced drivers, and some believe that the...view More

Oct 27, 2025 ? Industry News

-

The exhaust pipe is black, what's going on?Summary: I believe many car enthusiasts have experienced this: Why is the exhaust pipe white? What should I do if it's white? Is it a sign of a car problem? Recently […] I believe many car enthusiasts...view More

Oct 27, 2025 ? Industry News

-

Car modification knowledge: the benefits of changing the exhaust manifoldAbstract: The exhaust manifold is a key component that collects exhaust gases from all engine cylinders and discharges them out of the vehicle. The efficiency of the entire exhaust system depends on i...view More

Oct 27, 2025 ? Industry News

-

Introduction to Automobile Oil Return PipeAbstract: The function of a vehicle's oil return line: It allows excess oil to return to the tank, reducing fuel consumption. Not all vehicles have an oil return line. Return Line Filter […] The funct...view More

Oct 27, 2025 ? Industry News

Turbocharger Up Pipe is a core connecting component in the exhaust system of turbocharged engines, and Turbocharger Up Pipe is also one of the key automotive pipe fittings independently developed and produced by JIATIAN. As an important link between the exhaust manifold and the turbocharger turbine housing, Turbocharger Up Pipe is mainly applied to diesel engines and V-type engine layouts, responsible for guiding high-temperature and high-pressure exhaust gases to the turbocharger’s exhaust side to ensure the normal operation of the turbocharging system.

1. Working Principle of Turbocharger Up Pipe

The operation of Turbocharger Up Pipe is closely linked to the turbocharging system’s working logic:

After the engine burns fuel, the exhaust manifold collects high-temperature (up to 900℃) and high-pressure exhaust gases;

The Turbocharger Up Pipe transports these exhaust gases to the turbine impeller in the turbocharger’s turbine housing;

The high-speed flow of exhaust gases drives the turbine impeller to rotate, which in turn drives the coaxial compressor impeller to rotate, compressing fresh air into the engine cylinder to improve combustion efficiency and increase engine power.

2. Product Performance Comparison Table

| Performance Index | JIATIAN Turbocharger Up Pipe | Conventional Carbon Steel Up Pipe | Industry Standard Requirements |

|---|---|---|---|

| Material | High-grade stainless steel | Ordinary carbon steel | Corrosion-resistant alloy material |

| High-temperature Resistance | Sustains long-term operation at 950℃ | Deforms at 600℃ for long-term use | Resists ≥800℃ exhaust temperature |

| Corrosion Resistance | Resists exhaust acid corrosion for 80,000 hours | Corrodes and leaks after 30,000 hours | Corrosion resistance ≥50,000 hours |

| Welding Precision (laser welding) | Weld seam error ≤0.02mm (equipped with 4 automatic laser welders) | Weld seam error ≥0.1mm (manual welding) | Weld seam error ≤0.05mm |

| Customization Capability | Supports single-piece to mass production customization | Only fixed specifications available | Basic specification customization |

JIATIAN has 10 CNC fully automatic pipe bending machines, 2 large-scale brazing furnace assembly lines and other advanced equipment, which can ensure the stable realization of the performance indicators of Turbocharger Up Pipe in the table.

3. Application Cases

Heavy-duty diesel truck engine supporting: A domestic commercial vehicle manufacturer adopted JIATIAN’s Turbocharger Up Pipe for its 6.8L diesel engine model. After 500,000km of road testing, the product had no deformation or leakage, and the turbocharging system response efficiency was maintained at over 95%, which was 12% higher than that of the original matching product.

Off-road vehicle V-type engine modification: A professional off-road vehicle refitting enterprise customized a special-shaped Turbocharger Up Pipe for its 3.0T V6 engine model through JIATIAN’s full-process customization service.?

4. Maintenance Guide for Turbocharger Up Pipe

Reasonable maintenance can extend the service life of Turbocharger Up Pipe. JIATIAN combines its product characteristics and industry experience to sort out the following maintenance points:

| Maintenance Stage | Specific Operations | Core Attention Points |

|---|---|---|

| Daily Inspection (per 10,000km) | Check the connection flanges of the up pipe for looseness, and observe whether there is exhaust gas leakage at the welds | Do not use hard tools to knock the pipe body to avoid damaging the stainless steel structure |

| Regular Maintenance (per 50,000km) | Clean the inner wall carbon deposits of the up pipe (use professional carbon deposit cleaning agent), and check the pipe body for cracks | JIATIAN recommends using neutral cleaning agents to avoid corroding the high-grade stainless steel material |

| Fault Maintenance | If there is exhaust gas leakage, replace the sealing gasket first; if the pipe body is deformed or cracked, replace the whole pipe in time | When replacing, it is recommended to choose JIATIAN’s original matching products to ensure the matching degree with the turbocharging system |

5. FAQ about Turbocharger Up Pipe

Q: What is the key factor affecting the service life of Turbocharger Up Pipe?

A: The core factors include material high-temperature resistance and welding precision. JIATIAN’s Turbocharger Up Pipe adopts high-grade stainless steel and is welded by automatic laser welders and welding robots , which can effectively resist high-temperature oxidation and ensure the tightness of welds, thus extending the service life.

Q: Can JIATIAN provide customized services for non-standard Turbocharger Up Pipe?

A: Yes. JIATIAN has its own R&D and processing centers, and its water expansion corrugated pipe equipment and technology are at the industry leading level. It can provide full-process customized solutions from single-piece production to mass production for different industries and application scenarios, and complete the customization of non-standard Turbocharger Up Pipe according to the customer’s engine model and installation space.

Q: What will happen if the Turbocharger Up Pipe has poor sealing or cracks during use?

A: Poor sealing or cracks in the Turbocharger Up Pipe will lead to exhaust gas leakage, which will reduce the exhaust pressure entering the turbocharger turbine. This will weaken the turbocharging effect, resulting in decreased engine power, increased fuel consumption, and even abnormal noise in the exhaust system. In severe cases, leaked high-temperature exhaust gas may scald surrounding components and cause safety hazards. JIATIAN’s products adopt high-precision laser welding (weld seam error ≤0.02mm) to avoid such risks.

Q: Is there a connection between the design of Turbocharger Up Pipe and the response speed of the turbocharger?

A: Yes. The inner diameter, bending angle, and length of the Turbocharger Up Pipe directly affect the flow rate and resistance of exhaust gas. If the pipe diameter is too small or the bending angle is too large, exhaust gas flow resistance will increase, leading to a delay in turbocharger response (i.e., “turbo lag”). A reasonable design can reduce exhaust resistance and improve turbo response speed. JIATIAN relies on CNC automatic pipe bending machines and hydraulic internal forming equipment to achieve precise shaping of the pipe’s structure, matching the turbocharger’s response needs of different engines.

Q: Can the Turbocharger Up Pipe be modified to improve engine performance, and what points need to be paid attention to during modification?

A: Proper modification of the Turbocharger Up Pipe (such as optimizing the inner diameter and reducing bending resistance) can help improve exhaust efficiency and enhance turbocharging effect, thereby increasing engine power. However, modification needs to pay attention to three key points: first, ensure the material’s high-temperature resistance to avoid deformation under high load; second, match the size of the exhaust manifold and turbocharger turbine housing to avoid installation mismatch; third, comply with relevant emission regulations. JIATIAN can provide customized non-standard pipes for modification scenarios based on engine parameters.

English

English Espa?ol

Espa?ol